Product Carbon Footprint Reduction in the Smart Factory

Reducing the carbon footprint of products is a priority for companies, especially those operating in the industrial sector. Smart Factories are leading the way towards a more sustainable world with strategies and solutions that minimize environmental impact. Discover how Smart Factories are reducing product carbon footprint. Learn about the technologies and strategies used to achieve more sustainable production. To reduce the product carbon footprintSmart Factory or intelligent factory is implementing a set of technologies that allow from a intelligent waste management to a reduction of energy consumptionachievements of the resilient and sustainable factories which translate into an appreciable improvement of the environmental impact of production. As the industrial sector is one of the largest emitters into the environment, sustainability in manufacturing is an increasingly important element in industrial environments. The organizations that make up this sector are under increasing pressure to implement sustainable practices that include efficiency in the use of resources in the factory and the incorporation of sustainable production elements. Carbon footprint measurement It is clear that the concepts of Industry 4.0 and sustainability go hand in hand. The Smart Factory emerges as an indispensable element to address the challenges caused by climate change by leveraging technology to improve production processes, enable a reduction in carbon emissions or incorporate clean technologies in industry. The first step to reduce the carbon footprint of a product is to measure its carbon footprint, since the data obtained will allow the definition of the optimal strategy to reduce it. A solution such as Smart Factory by aggity plays a key role in this process, as it enables real-time data collection and detailed analysis for subsequent decision making. The platform integrates a series of tools that take advantage of the the power of technologies such as the Internet of Things (IoT). thanks to sensors scattered along the entire production chain to collect data on the energy consumptionthe greenhouse gas emissions and other relevant environmental indicators. The data collected is transmitted to centralized platforms, where artificial intelligence is applied to improve production; in other words, a set of algorithms is in charge of processing it to identify areas for improvement in terms of efficiency and sustainability. Process optimization One of the advantages of Smart Factories is that they achieve maximum energy efficiency in production. energy efficiency in production thanks to process optimization. Thus, the use of process automation tools through robots and autonomous systems increases efficiency, and at the same time, minimizes energy consumption and improves waste management in the smart factory, which also helps to reduce waste. Real-time monitoring, meanwhile, allows smart factories to constantly assess their environmental performance. The incorporation of energy management systems provides detailed information on the use of resources and, with the information obtained, the Smart Factory managers can implement changes in the processes with the aim of reducing the carbon footprint. Traceability and transparency The fact that customers are also becoming increasingly aware of the use of sustainable materials in the manufacture of products is leading to numerous innovations in manufacturing. Companies are increasingly looking at the materials they use in manufacturing or ease of recycling when designing their products and packaging. In this way, they contribute to improving sustainability and also to building customer loyalty. Traceability and transparency in the supply chain play a prominent role here, enabling customers of industrial companies to trace the origin of materials and assess the environmental impact at each stage of manufacturing. Thanks to the use of technologies such as blockchain or RFID, the Smart Factory can record and verify every step of the manufacturing and distribution process.

Digital Transformation Indicators

Digital transformation is essential for the evolution of companies. In this article, we will explore the key indicators that can help organizations measure and optimize their digitization processes and thus achieve their objectives. Discover how to measure and improve your digital transformation process with the right metrics. Establish effective KPIs to achieve your objectives more efficiently. There are numerous digital transformation indicators that make it possible to evaluate the status of the digitalization processes undertaken by organizations, as well as to establish comparisons with respect to the situation of other companies. This series of indicators also makes it possible to measure the success of the company’s digital transformation. Although there are different ways of analyzing the situation of an organization that has undertaken different digitalization processes, some of the most important indicators are the following. Digital ROI (Return on Investment) It is an indicator that attempts to measure the effectiveness of digital investments in terms of financial returns. It can be calculated with the formula (Profit – Costs) / Costs. In general, it is one of the digital efficiency metrics The most widely used by companies as it provides insight into the impact of investments in digitalization, for example, the ROI in social networksThe company’s investment in process improvement and whether that investment has translated into increased revenues or reduced costs and customer satisfaction. With the Digital ROI , companies can optimize their investments and know what type of investments generate a more positive return. Digital transformation KPIs Digital transformation KPIs or key performance indicators enable companies to assess their performance and make progress towards their strategic objectives. When talking about digital transformation, KPIs measure the progress in the implementation of the digitization strategy that is being carried out. Measurement metrics typically include, among other things, technology adoption analysis, digital customer experience measurement or an assessment of the company’s digital maturity. Digital Customer Experience (CX) Since all companies exist because of their customers, measuring their degree of satisfaction is essential. Platforms such as Digital Customer Engagement by aggity allow you to create metrics for customer satisfaction, online conversion rate, customer retention and response time to customer inquiries. This solution, in addition to providing accurate data thanks to the use of technologies such as AI or Big Data, facilitates the omnichannel communication of companies with their customersThe new, personalized marketing campaigns and real-time communications, which directly contribute to the customer loyalty. This category also includes other items such as the customer retention rate, the number of users who abandon a purchase or the reasons why a customer is dissatisfied with the after-sales service provided. Employee satisfaction index Just as it is necessary to measure customer satisfaction, one of the most commonly used business transformation metrics is that which measures employee satisfaction with respect to the digitization initiatives that have been implemented. In an environment like the current one, affected by a major talent crisis, it is essential to measure the level of satisfaction of a company’s employees in relation to the transformation initiatives and the technology implemented. This is an indicator that will also show the impact of digitalization on the work environment and whether these digital transformation processes are increasing efficiency. Based on the data provided by this metric, solutions such as BesTalent IA by aggity, will allow to improve the organization’s talent management strategy. Innovation culture assessment This parameter is a consequence of the previous one. By assessing the culture of innovation, companies can analyze how willing employees are to adopt new ideas to improve production processes or whether they are willing to embrace the use of new technological tools. Process automation monitoring Finally, we highlight the importance that, among the digital transformation indicators, has the monitoring of process automation. This type of metrics, which are widely used in the field of Industry 4.0The number of automated processes that a company has and whether the different processes are types of industrial automation have provided a time reduction in production processes or if they have improved quality, increased efficiency or saved time and resources.

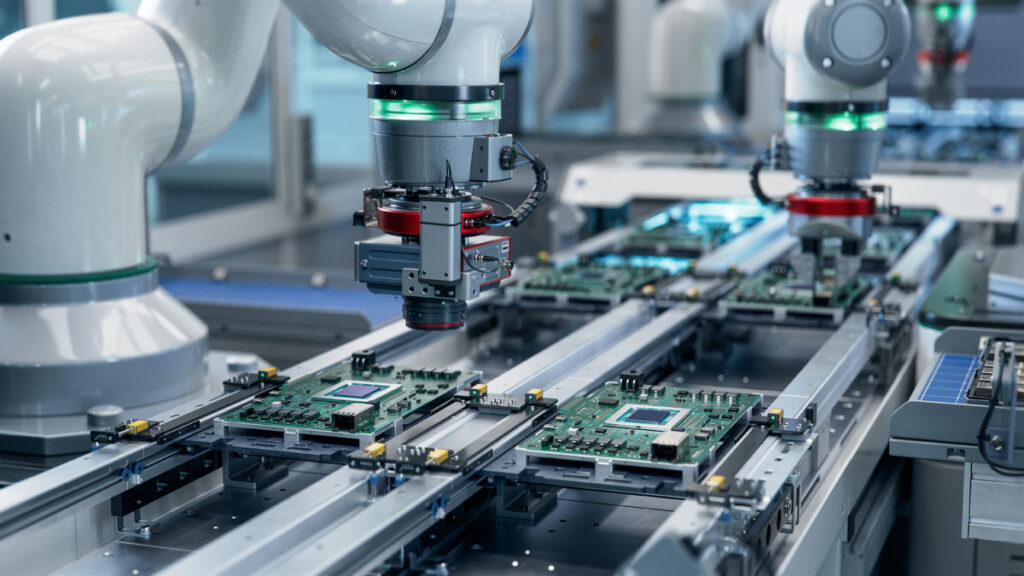

Industrial Robotics in the Smart Factory

Industrial robotics is transforming factory operations. However, although it seems that the transformation of the industry is recent, the road to the smart factory started years ago. In this article we take a closer look at this revolution and how it drives production efficiency. Discover how industrial robotics is revolutionizing the Smart Factory. Explore examples and benefits of this technology. Industrial robotics in Smart Factories represents an opportunity that companies are taking advantage of to drive innovation, improve product quality and thus become much more competitive organizations. We find ourselves in a new era which, thanks to the automation of industrial processesthe use of the so-called Industrial Internet of Things (IIoT) or the use of tools that allow the digitization of production are making us face a more important Industrial Revolution than the one that took place at the end of the 18th century. Industrial Robotics in the Smart Factory The history of industrial robotics dates back to the 1950s when the first industrial robots designed for very simple tasks such as welding began to be developed. From that moment on, the first programmable robots began to be developed and it was in the 70’s when the first machines that allowed the automation of manufacturing began to be implemented. Today, the role of robots in the production smart factory and in the Industry 4.0 has come a long way thanks to the incorporation of the so-called cobots (collaborative robots) and advanced robotics, with robots incorporating technologies such as artificial intelligence to improve the production efficiency o that allow adapting to changing production conditions to speed up decision making. Industrial robotics applications There are numerous uses of industrial robotics by companies in different production sectors. One of the most common is the automation of assembly lines. In this example, robots perform repetitive tasks, such as the assembly of components or parts, in a precise manner that increases production speed and improves product quality. The same is true for the use of robots for material handling and transport. Mostly used in the food industry, in this case the robots are in charge of packaging the products, which translates into an optimization of the supply chain. supply chain optimization delivery processes can be accelerated. The applications of industrial robotics go beyond that. Some of its applications have to do with automation and quality control in such a way that robots, equipped with cameras and sensors, are able to examine products for defects. It is typically used in industries with advanced manufacturing technology such as electronics or medical device manufacturing. Undoubtedly, one of the sectors in which industrial robotics is having the greatest impact is the medical sector, where robotic surgery allows less invasive and less dangerous operations to be performed on patients. Enabling technologies There are different technologies and solutions that favor robotics and automation to end up in the integration of production systems in any company. Thanks to the use of technologies such as Artificial Intelligence or big data, a solution such as Smart Factory by aggity allows to know the real situation of a Smart Factory. This type of tool can perform predictive maintenance on equipment, enable more effective warehouse automation or improve energy efficiency in production. energy efficiency in production by knowing precisely when, for example, a peak in demand is going to occur. Artificial intelligence and machine learning in robotics allow robots not only to perform programmed tasks, but also to learn, adapt to changing situations in real time and make decisions to, for example, improve the productivity of a given machine at a specific time.

Examples of Digital Transformation

Following the pandemic, digitization projects in organizations have multiplied and companies are seeing how digitization improves their production processes and efficiency in an increasingly competitive environment. Let’s take a look at some of the digital transformation. Discover real cases of companies that have boosted their success through digital transformation. Learn from their strategies and achievements. In this article we will explore different success stories in digital transformation of companies and sectors that have achieved impressive results thanks to it. From optimizing internal processes to creating exceptional customer experiences, these examples of digital transformation illustrate how a commitment to digitization can drive efficiency, innovation and business success. Digital transformation in retail One of the sectors in which digital transformation has had the greatest impact is retail. The rise of e-commerce has been driving the digitization of companies in the retail sector for some time now. Solutions such as Digital Customer Engagement by aggity, which improve the online and offline customer experience, what we call the phygital experience, with a high degree of customization, are responsible for the interest of the companies in this sector in implementing the latest emerging technologies in the market. Thus we see how retailers dedicated to textiles offer tools to try on a garment without having to go through the fitting room or those dedicated to the sale of furniture allow you to check how it will look in the user’s room before buying it. Another clear example of the digital business transformation in this sector is Amazon, a company that has gone from being a company dedicated to online book trade to become the e-commerce giant it is today. The multinational has invested in different technological innovation solutions, such as the use of machine learning algorithms to recommend products to customers based on their previous purchases or technologies. Internet of Things (IoT) or of process automation to improve the management and efficiency of your warehouses. Digital transformation in the industry The technological innovation is playing a key role in achieving the goal of the so-called «green economy». Industry 4.0 in all industrial sectors. The use of solutions such as Smart Factory by aggity are enabling the development of the smart factory and connecting machines and devices throughout the plant, which facilitates the real-time data collection to facilitate decision making data-driven, allows for adapting to peak demand, implementing predictive maintenance to prevent breakdowns, as well as meeting the challenge of reducing the energy bill. An example of a good digital transformation strategy General Electric, which has adopted a number of technologies to take advantage of the Industry 4.0 potential and that thanks, among other things, to the use of the artificial intelligence and machine learning has enabled it to develop services of predictive maintenance based IoT for its motors and industrial equipment, which has improved efficiency and reduced costs for customers. Digital transformation in entertainment The digitization of business reaches all types of companies, including those operating in the entertainment sector, whether they are more modern, such as Netflix, or more traditional, such as Disney. These streaming platforms have completely transformed the way people consume audiovisual content. The rise of digital culture has been taken advantage of by these companies that make use of big data and analytics to adapt to the tastes and preferences of their customers, and thus improve customer engagement. But that digitization has also boosted companies in the video game industry. Companies in this niche market have pushed the development of mobile applications or have adopted virtual reality and augmented reality to offer more immersive gaming experiences. The Google case One of the most important examples of digital transformation is Google, due to the number of elements it brings together. The company is a leader in search engines, online advertising and cloud computing services. To improve operational efficiency, Google is clearly betting on artificial intelligence and big data to drive its digitalization.

Characteristics of Automation in the Smart Factory

Automation in the Smart Factory is a cornerstone of digitalization in industrial companies. This article explores the defining characteristics of this revolution: from operational efficiency to improved quality, automation is shaping the future of manufacturing. Explore the key features of automation in a Smart Factory. This is not a new concept, as automation has long driven operational efficiency in industrial environments. However, the features of automation in the Smart Factory are making innovation in manufacturing in industrial environments much faster. This is because the Smart Factory is benefiting from the incorporation of different technologies that achieve efficient processes, improved product quality and resource optimization. Technologies such as industrial robotics, the Internet of Things (IoT), systems integration or the different types of industrial automation are types of industrial automation that are enabling a very rapid evolution that has not been seen since the beginning of the first industrial revolution. Automation in the Smart Factory has, therefore, different characteristics that make it different from other processes of the past. Some of these keys are as follows: Operational efficiency One of the most salient features of automation in the Smart Factory is the ability it has to drive operational efficiency to previously unseen levels. Automated production allows the execution of the most repetitive tasks. This minimizes errors and drastically reduces downtime because automated control systems ensure that operations run consistently, leading to higher productivity and reduced production variability. Flexibility and adaptability Flexibility and adaptability are two of the fundamental characteristics in the technological innovation of the Smart Factory and have turned it into a model that allows, for example, improving the supply chain or obtaining cost reductions. Thanks to the flexibility provided by automation, factories can adjust and adapt to changes in production, so that production volumes can be altered or even the design of a product can be changed easily and efficiently. If flexibility is important, adaptability will play an increasingly important role. Solutions such as Smart Factory by aggity, which incorporates machine learning and artificial intelligence technology, enable companies to analyze data in real time to identify production problems and prevent losses, predict machine failures and optimize processes on an ongoing basis. This achieves excellence in intelligent manufacturing. By being able to run real-time monitoring, the production process means analyzing and presenting production data in order to have a detailed view. Error reduction In traditional industrial environments, human error is common. With the adoption of automation, these errors virtually disappear. This is one of the key characteristics of industrialization 4.0, as automated systems can perform repetitive, high-precision tasks without fatigue or errors, resulting in improved product quality and increased productivity. Automation also minimizes the need for quality control and production problem management resources, leading to significant cost savings. Improved security Finally, another of the most important Smart Factory automation features has to do with safety. One of the most obvious benefits is the reduction of workers’ exposure to occupational hazards as those more dangerous tasks can be performed by robots, so that the employee does not have to deal with potentially dangerous work and can focus on tasks of greater value to the companies.

Predictive Maintenance in Smart Factory – Aggity

Predictive maintenance is an advanced technique used in Industry 4.0 and, specifically, in the Smart Factory, which uses data, sensors and analysis in order to predict errors and failures that may occur in machinery and industrial equipment so that the factory can anticipate their solution. Discover how predictive maintenance increases efficiency and reduces costs in the Smart Factory. aggity is one of the most experienced companies in the Smart Factory environment. It specializes in the modernization of traditional factories, guiding them towards Industry 4.0 with innovative solutions, such as Smart Factory by aggity that, thanks to their use of the Internet of Things (IoT)Big Data or Artificial Intelligence, provides a complete, modern, configurable and modular system to manage and control the activities of production, quality, materials and, of course, the smart factory maintenance. This maximizes productivity and provides optimal industrial asset management. These types of solutions are essential in industrial environments to improve their operational efficiency and also to increase the useful life of the equipment, which translates into reduced maintenance costs. In addition, implementing predictive maintenance in a production plant has other advantages such as reducing downtime and improving production and energy efficiency. But how does predictive maintenance work in the Smart Factory and what benefits does it provide? Data collection In order for a predictive maintenance process or predictive maintenance predictive maintenance process to be successful, it is necessary to nurture it with data. The equipment and machines that make up a Smart Factory are equipped with a countless number of industrial sensors that constantly monitor their operation. The monitoring of industrial assets provides relevant data such as the temperature at which industrial machinery is working , energy consumption or the loss of operating efficiency of a machine. All this data is transmitted in real time to a data management platform that stores and processes the information. Data analysis From this moment on, and with the use of algorithms, a real-time data analysis is performed to identify patterns and anomalies that may occur in industrial machinery, many of which would go unnoticed by a worker. These algorithms can detect subtle changes that a human operator might miss, such as an increase in the temperature of an engine. Anomaly detection Anomaly detection is therefore one of the main values of a predictive maintenance system. Thanks to the ability of smart factory monitoring systems to identify unusual patterns and data, managers can uncover problems that are affecting machines or equipment. In this case, the platform will send an alert to the maintenance managers to take preventive measures before a serious machine failure occurs. Predictive models One of the keys to the predictive analytics needed to develop predictive maintenance lies in the creation of models based on historical data and recurring patterns. For example, based on the use of big data in maintenance and advanced analytics technologies, the algorithms that make up the platform know when it is necessary to change a part on a given machine. Thanks to this predictive diagnosis, Smart Factory operators can plan and schedule maintenance more efficiently and at the most appropriate times, avoiding unscheduled downtime. In addition, all asset maintenance interventions are controlled and managed through the platform. Improved productivity Incorporating a predictive maintenance system in a Smart Factory drives productivity improvement by reducing downtime, improves planning and enables production optimization. All this translates into an increase in manufacturing ratios and a greater capacity to adapt to demand and market circumstances, which has an impact on improving the factory’s profitability.

Examples of Cobots in the Smart Factory: Innovative Automation

Collaborative robots, also called cobots, are one of the indispensable elements in Industry 4.0 and are already transforming factory production by improving both the efficiency and safety of manufacturing facilities. Discover how cobots are revolutionizing the Smart Factory with innovative automation. Cobots are being used in industry on numerous occasions and are already bringing about a major revolution in manufacturing innovation. There are currently many examples of cobots that are providing innovative automation and producing production line optimization, pillars of smart manufacturing. The transformation that industrial environments are undergoing would not be possible without the help of the collaborative robot. It is true that the automation in factories has long been incorporated into the production processes, but with the use of cobots, the next step is being taken, which is to achieve a innovative automation . Thanks to her, the cobot integration and the use of smart factory technologies like Smart Factory by aggityplant and production managers see how a new plant is produced. human-robot collaboration This allows employees to dedicate themselves to tasks of greater value to the company and to do so with high levels of safety, since the riskier tasks are assimilated by the collaborative robot. Here are some examples of cobots in the smart factory. Assembly of parts The main feature of cobots, which are already a key part of smart factory work, is that they are designed to work safely alongside humans. These collaborative robots are equipped with advanced sensors that make it possible for them to adapt to an environment with a permanent presence of people and, since their programming is flexible, workers can teach them to perform different tasks without the need for programming skills. Parts assembly is one of the environments where production efficiency has improved significantly with the use of cobots. In this sense, the automotive sector is one of the sectors in which collaborative robots are being used the most. This is one of the most common cobot success stories, as in many automotive assembly plants these robots work alongside workers to perform repetitive and dangerous tasks, such as component assembly, welding and body painting. Cobots are also widely used in the electronics industry, where they are used in the assembly of circuit boards as they ensure greater precision and speed in component placement. Packaging and palletizing In industrial robotization , cobots are increasingly being used for packaging and palletizing products. One of the sectors that is developing a greater number of cobot solutions is the food industry. Organizations involved in food processing are employing this type of collaborative robot for product packaging, labeling and handling. The great advantage of its use is that, in addition to increasing productivity in the Smart Factory, it improves automation safety by preventing food contamination. The use of cobots also extends to palletizing, thus resulting in a logistics optimization. Companies in this sector have seen how the use of collaborative robots makes it possible to optimize space in warehousesas well as reduce the physical strain on workers y streamline operations and receiving. Handling of heavy materials Other examples of cobot applications relate to the handling of heavy materials, which contributes to increased occupational safety. In this case it is a great help for those employees who have to move heavy loads that could cause injuries. Organizations from different sectors are already using cobots in their innovative automation processes. The most relevant, the manufacturing industry and distribution, which employ cobots to lift and move heavy components on assembly lines, but they are also used in the construction sector to transport heavy materials on difficult terrain or in confined spaces. Customer service and support Another example can be found in cobots dedicated to customer service and assistance. In this case, we can see more and more collaborative robots in stores, airports, hotels, restaurants and other public places to provide information and assistance to customers. Cobots can guide customers through the store, assist in finding items, move products and process payments. At airports we are already more than used to interacting with a collaborative robot to get a boarding pass or obtain information about the status of a flight.

Types of Industrial Automation in the Smart Factory

In the era of Industry 4.0, automation has become one of the pivotal elements of any production plant’s strategy as it streamlines processes, improves efficiency and reduces costs. Explore with aggity the types of industrial automation crucial for a successful Smart Factory. There are different types of industrial automation, each with different technologies and approaches. From robots and CNC machines to process control systems, automation covers a wide range of applications. For this reason, choosing the right type of industrial automation is crucial to meet the specific needs of each smart factory. In the same way that the way a factory in the food sector works is not the same as one in the automotive sector, the automation needs to be covered are also different. In this article, we will explore the main types of industrial automation and how they can revolutionize modern production. Fixed or rigid automation It is one of the oldest types of industrial automation used in production lines. We are talking about one of the key elements in the optimization of processes in industrial organizations. Fixed automation has been used for decades in a variety of industries, from manufacturing to logistics to automated supply chain. It consists of programming machines or systems to perform a predetermined sequence of steps, generally in a linear and sequential flow. It is a very effective technology when processes are standard and do not require constant adaptation. Its main advantage is reliability, which ensures that human error is reduced to a minimum. Programmable automation In this case, it is an advanced form of automation that offers greater flexibility and adaptability compared to fixed or rigid automation. In programmable automation, the control systems or industrial robotics elements of a smart factory are programmed to perform specific tasks, but, unlike the previous one, it has the ability to modify their behavior to to adjust to changing conditions or unforeseen situations. . Flexible automation Flexible automation goes one step further. While programmable automation relies on predefined instructions, flexible automation leverages Artificial Intelligence (AI) and machine learning to adapt and respond to new conditions and scenarios in real time. This type of industrial automation is primarily used in factories that experience variable workflows or require interaction with unstructured data. To adapt manufacturing processes and improve production efficiency. One example is collaborative robots or cobots. Flexible automation tends to be confused with adaptive automation, but the latter has the ability to adapt to changes in the environment or production process automatically and without the need for human intervention. Process control automation This typology focuses on improving efficiency, product quality or adjusting the use of materials to obtain cost reductions. To this end, it employs automated systems, industrial sensors and other elements such as the Internet of Things (IoT) that enable the monitoring and optimization of processes in order to reduce human intervention and minimize errors. In this regard, a market benchmark solution such as PlanetTogether by aggity enables finite capacity planning and scheduling of production activities, taking into account the availability of resources and materials. One of the components of process control automation is Computer Numerical Control (CNC) , which allows components and parts to be produced faster, more accurately and cost-effectively. Robotic automation Also known as robotic process automation or RPA, it employs software robots to automate repetitive tasks that interact with systems and applications in the same way a user would, but with greater speed and accuracy. Robotic process automation is commonly used in business environments where many manual and routine tasks are performed, such as data entry, reporting and data reconciliation. One of the many benefits of RPA is that it frees employees from this type of work, allowing them to focus on other, higher-value work. Other types of industrial automation There are other types of automation that, in combination with different manufacturing technologies, aim to continuously improve production efficiency. These include, among others, assembly automation, for the assembly of parts; warehouse automation, to optimize storage; or inspection and testing automation, to assess product quality.

Benefits of Industrial Automation

In the era of Industry 4.0, industrial automation has become a crucial component for the success of production plants. The smart factory, with its focus on integrating advanced technologies such as the Internet of Things (IoT) and big data, is leading this transformation. Discover the benefits of industrial automation in the optimization of a Smart Factory. The benefits of industrial automation in smart factories range from process optimization and reduced operating costs to improved quality and sustainability. Next, we will discuss what the advantages of industrial automation are and how it provides valuable information to plant and production managers who can leverage these technologies to build a more efficient and competitive Smart Factory. In industrial automation , specific technologies are used to perform production tasks and processes without the need for direct human intervention. Thanks to its use, production efficiency is improved, as well as the quality of the products. In order to carry it out, automatic control systems, sensors and actuators, robotics, sensors, control and data analysis software, as well as tools and platforms such as Smart Factory by aggity, which covers all the needs of organizations in the industrial sector, are used. Among the benefits of industrial automation we can highlight the following: Increased productivity One of the main advantages of using industrial automation technologies is that it allows machines and systems to perform tasks faster and more efficiently than an employee would, resulting in increased productivity. In this sense, industrial automation makes it possible to minimize production cycle times by eliminating downtime and optimizing work sequences, resulting in faster and more efficient production. Improved product quality Robotization in manufacturing is already a reality so employing automation in an Industry 4.0 environment ensures consistent and controlled production, thereby improving the quality of the products being manufactured. This is possible because the defects that a human can commit are reduced, which also results in greater innovation in the plant . In addition, there is an improvement in the sustainability and manufacturing The automated supply chain makes better use of raw materials and reduces the amount of waste. Reduction of operating costs Another long-term benefit of industrial automation is that it helps to reduce costs by minimizing errors, reducing labor requirements and reducing production times. It is true that the initial investment in the implementation of automation technologies that improve process optimization will be high, but the return on investment will be much higher. Improved occupational safety This is one of the keys to industrial automation, since the work that was previously done by human employees is now being performed by machines or tools. In this way, the worker can not only dedicate himself to the performing tasks of greater value to the organizationThe company’s safety at work is improved because it can stop performing certain more dangerous jobs, such as handling chemicals or working in high temperature environments. Production flexibility The last major benefit is that automated systems can be reconfigured and programmed to suit different tasks and products. This ensures greater production flexibility as the use of automation tools allows smart factories to quickly adapt to changes in demand and modify production configurations. All of this results in greater agility in responding to changing needs and continuous improvement in operational efficiency.

Predictive analytics in digital transformation

Predictive analytics in digital transformation is an indispensable resource for companies seeking to boost their digitization processes and optimize business and operations. Through advanced data analytics techniques, business leaders can anticipate trends, forecast demands, and make informed decisions that improve performance and sustainability. Discover how predictive analytics is driving transformation in business and operations. In this content we will explore the fundamentals of predictive analytics, its applicability in various industries, and future trends. You will find out what predictive analytics is and how companies in different industries are implementing it. Introduction to predictive analytics Predictive analytics is a type of data analysis that employs statistics, big data, machine learning data mining or predictive algorithms, among other techniques, to predict what may happen in the future and make data-driven decisions that will give the organization a competitive advantage. For predictive analytics to work, a number of important conditions must be met: the main, obvious one is that the data must be of good quality. The basis on which any type of data analytics is based is that the data is correct and complete, otherwise the decision making will be wrong. On the other hand, the use of machine learning algorithms will allow the optimization of operations and the appropriate trend analysis. Importance in business and operations Predictive analytics is becoming increasingly important for organizations in different sectors, which see in the so-called business intelligence an essential element to realize a more effective business intelligence trend analysis, a sales forecasting, predictive modeling, behavioral analysis and market analysis, and time series analysis. Already making use of predictive analytics in their business strategy are sectors such as healthcare, where it is used to identify patterns in medical data and predict disease; marketing, where predictive analytics can help to identifying potential customers, forecasting demand for products and services or in human resources, where it is used for predict job performance and improve hiring processes. Industry use cases Among all the sectors, the industrial sector is one of the ones that is using predictive analytics the most. Platforms such as Opera MES by aggityThe company has developed a new software, which facilitates the analysis and implementation of corrective actions and provides data in real time thanks to the use of machine learning, big data or the artificial intelligencehave become an essential ally for the development of the so-called Industry 4.0. In general, companies in the industrial sector are employing predictive analytics to establish risk management and improve the supply chain. . One of the areas in which predictive analytics is being used most in the industry is to predict failures and problems in industrial machinery and equipment. Through the use of real-time and historical data, machine performance, environmental conditions and operating variables can be predicted and patterns suggesting impending problems can be identified. In addition, the industrial sector uses predictive analytics to predict the demand for products and raw materials in the supply chain. Thanks to it, they can predict market trends and perform behavioral analysis, so that companies can optimize their inventories and adjust their production levels to meet expected demand. This helps to avoid excess or shortage of inventory, reducing warehousing costs and improving supply chain efficiency. Future trends and conclusions There is an essential element that will play an important role in the development of predictive analytics: big data. The ability of companies to store, manage and analyze huge amounts of data is enabling the growth of business intelligence. With its use, a much broader data visualization can be performed to make more effective decisions.