aggity ‘manufactures’ the competitive opportunity of the decarbonization challenge for industry

Together with TAI Smart Factory, shows at Advanced Factories 2024 the power of combining its Smart Factory by aggity and GreenwAIs by aggity platforms.

- aggity finds that what is driving industrial companies is the energy transition imperative and, specifically, the new EU CSRD directive on corporate sustainability reporting.

- The new CSRD will affect 50,000 European companies -5,000 in Spain- by 2027.

Madrid, April 8, 2024 – The Spanish technology multinational aggity highlights the competitive opportunity that the challenge of decarbonization means for companies in the industrial sector and the risk of being left out of the market for those that delay taking it on by implementing technology in three major areas: digitization, extraction of the value of Artificial Intelligence (AI) and continuous monitoring to ensure sustainability.

aggity notes that, although still important, the high cost of energy is no longer the main lever for energy efficiency improvement and decarbonization projects in industrial companies. Instead, according to aggity, what is currently driving companies is the energy transition imperative to meet the twin goals of 30% emissions reduction by 2030 and net zero emissions by 2050, and specifically, the European Union’s (EU) new CSRD on corporate sustainability reporting.

The CSRD, which came into force in January 2023, is a revision of the NFRD Directive on non-financial reporting and strengthens the reporting requirements with a special focus on ESG (Environmental, Social and Governance) sustainability. The standard also extends its compliance obligation to more companies. Thus, in 2025 it is mandatory for listed companies and companies of public interest; in 2026 for large companies with more than 40 million euros in turnover, 250 employees or more than 20 million in assets; and in 2027 for SMEs.

Thus, in 2027 around 50,000 companies in the EU -5,000 in Spain- will be subject to the new regulation, including companies in the industrial sector which, according to MITECO data for 2021, is responsible for 22.4% of greenhouse gas (GHG) emissions, second only to the transport sector (29.6%).

Sustainable Industry 4.0: measuring, acting and reporting

In this context, together with the company TAI Smart Factory and to make Sustainable Industry 4.0 a reality, aggity shows in Advanced Factories 2024 the power of combining its Smart Factory by aggity platform, which increases OEE (Overall Equipment Effectiveness) up to 16% and reduces energy consumption and CO2 footprint up to 15% and 21%, respectively; with its new GreenwAIs by aggity platform.

Regarding Smart Factory by aggity, aggity continues its evolution and has reinforced its MES (Manufacturing Execution System), Opera MES by aggity, with TAI Smart Factory MES and has also integrated TAI’s maintenance management system (CMMS) into the platform, in addition to applying the capabilities of analytics and Generative AI to factory management.

In this sense, aggity presents at the Industry 4.0 Congress of the fair the case of success in the application of Generative AI -specifically, IBM Watsonx- to optimize maintenance in the plants of the Spanish manufacturer of frozen dough for bakery and pastries, Europastry.

As a key complement to meet sustainability and ESG reporting requirements, aggity brings to Advanced Factories, its new GreenwAIs by aggity platform, which integrates two major interconnected pieces. The first, the EMS (Energy Management System) works like a brain, capturing energy consumption information from meters and the MES system itself to provide criteria for action and to plan and execute production in order to optimize plant consumption and orchestrate generation. In this area, aggity integrates the SIAL solution and also has an agreement with Sener to commercialize the engineering EMS.

The second piece of GreenwAIs by aggity is IBM’s Envizi ESG suite, of which aggity is a Business Partner. The Envizi ESG solution fulfills several critical functions. First, it compiles in a single auditable repository all sustainability information, including energy consumption through EMS and carbon footprint data (Scope 1, 2 and 3). It also allows, through the use of advanced analytics, to predict and optimize the generation, purchase and use of energy. It also provides tools for reporting and monitoring of objectives and actions.

According to Pablo González, CEO of aggity Spain, “industry must carry out a transformation to ensure its energy transition and, although this requirement currently applies to listed industrial companies, it will reach all of them, with the sole exception of micro-enterprises” .In the coming years,” González adds, “industry will have to carry out a transformation to ensure its energy transition, “manufacturers will need to know the carbon footprint of all products entering their plants, demonstrate their commitment to energy transition and sustainability goals, and have the ability to report according to European Sustainability Reporting Standards (ESRS), and all of this is simply impossible without technology.”

According to Ignacio Tornos, aggity’s Industrial Products & Manufacturing Sector Leader, “we are committed to helping our customers in the industrial sector . to face challenges such as operating under complex legislation that is increasingly demanding in terms of sustainability and decarbonization of productive activity”. “With knowledge, competence, experience and technology.” – We are capable of turning the challenge represented by the EU’s ambitious green objectives into an opportunity and we must take advantage of a challenge that will undoubtedly require investment in order to continue moving forward and carry out reindustrialization in terms of sustainability,” said Tornos.

Últimos posts

aggity strengthens its commitment to sustainability as a SILVER partner of “Fundación Empresa & Clima”.

aggity participates in the IBM Ecosystem Summit 2024 with an applied case of Generative AI in the food industry

Aggity, together with the multinational Fortinet, present an exclusive event in Lima on the application of Generative AI in Corporate Cybersecurity.

aggity participates in Smart Ports: Piers of the Future

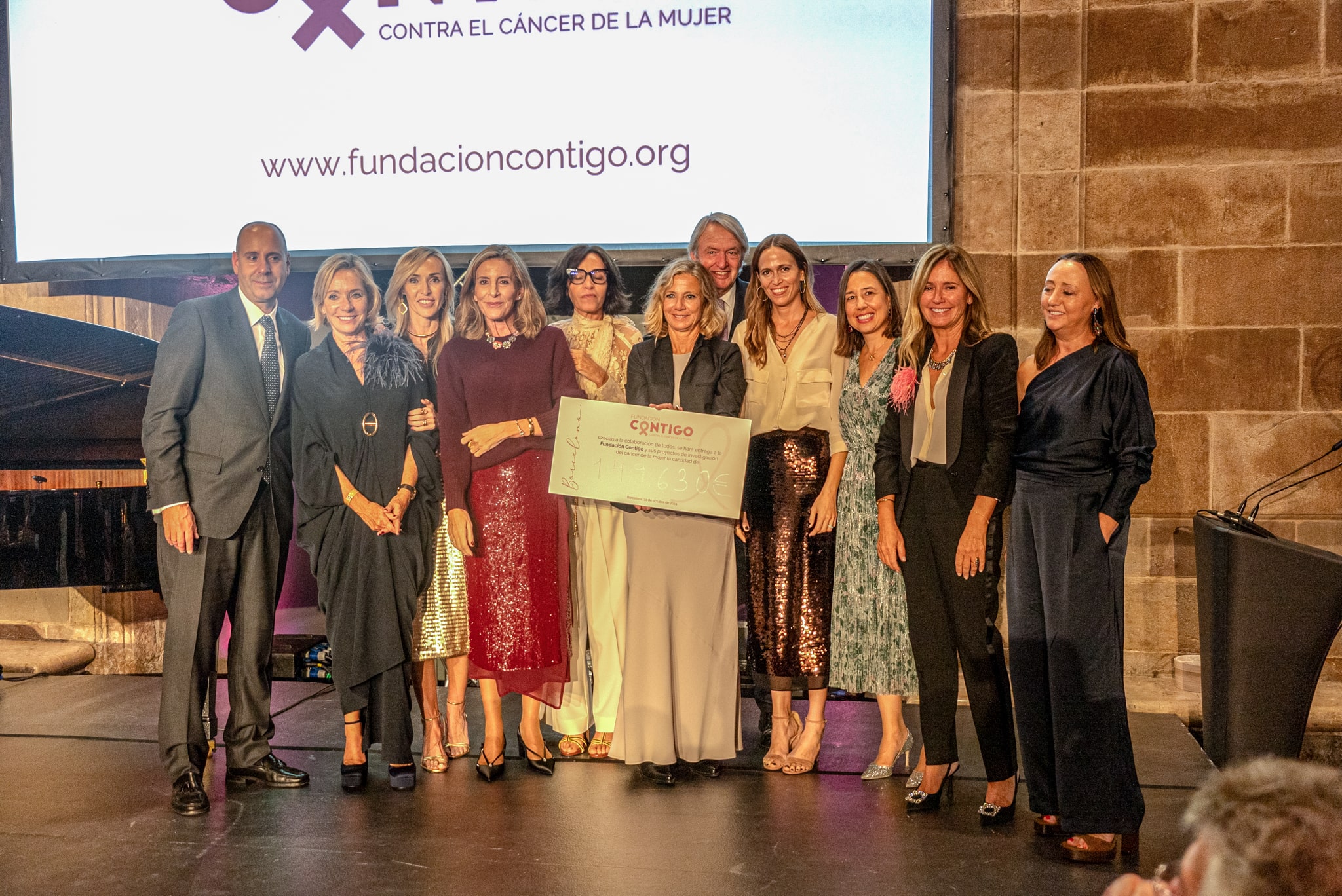

aggity Supports the Contigo Foundation at its Annual Dinner

Challenges and Opportunities of Generative AI in Industry: Our Experience at BNEW

Official Liferay Partner in Spain