Integrating corporate sustainability in the Smart Factory

Corporate sustainability is one of the central focuses of a plant manager’s strategy in a Smart Factory. Its main challenge is to integrate sustainable practices into operations that are already highly technical and to establish a robust sustainability agenda.

Tabla de contenidos

ToggleDiscover how your Smart Factory can lead in corporate sustainability, optimizing resources and production processes.

Corporate sustainability covers different fronts ranging from optimizing energy management to leveraging data to reduce waste or improving industrial waste management. Today’s factories not only have to be leaders in production, but they also have to be a benchmark in environmental sustainability. The optimization of manufacturing resources, real-time environmental monitoring or eco-efficient predictive maintenance are just some of the practices that need to be taken into account to make corporate sustainability a reality.

In this sense, the use of a solution such as Smart Factory by aggity, which covers the management and control of production, quality, materials and maintenance activities, makes it possible to achieve energy efficiency in manufacturing plants and give a boost to corporate sustainability. However, the establishment of energy efficiency and corporate social responsibility (CSR) policies is not only achieved with the implementation of this type of solutions, it also requires the design of a clear strategy in which there are different points to take into account. These are some of them:

Efficient automation

The incorporation of sustainable automation systems in the Smart Factory is one of the elements that most factories are currently betting on. The different types of industrial automation provide multiple benefits ranging from reducing the carbon footprint of production to establishing green process simulations or improving environmental management systems (EMS).

Energy efficiency is also one of the areas where the introduction of automated systems can improve the sustainability of factories, as they can manage energy consumption precisely and adjust the levels of energy needed according to demand. Green innovation in smart factories goes through these automation solutions, which also play a very important role in reducing waste by minimizing the waste of materials and resources.

Real-time monitoring

In the quest for the most sustainable and productive factory, real-time monitoring is a very relevant section. In this sense, the implementation of sensors and IoT (Internet of Things) systems allows instant adjustments to be made to adapt to the needs of demand and thus improve efficiency.

The use of IoT for sustainability is one of the most important developments to have occurred in industrial environments. Thanks to a factory’s IoT sensor suite, it is possible to analyze energy consumption and address the actions needed to achieve a emissions reduction in productionThe transmission and distribution network has also been improved, thus eliminating the need for problems in the supply chain and move towards a green supply chain.

Renewable energies

The use of renewable energy in manufacturing will not only improve corporate sustainability, but also help to obtain different environmental certifications for factories, reduce energy consumption costs and improve a company’s brand image.

Switching to cleaner energy sources not only responds to environmental demands, but also offers factories long-term economic and strategic benefits. The choice of one energy source or another will depend on the access to it, so that, although wind and solar are the predominant ones, it is worth analyzing whether the implementation of hybrid technologies can be more efficient for a production plant.

Additive manufacturing

Also known as 3D printing, additive manufacturing is becoming increasingly important in corporate sustainability by enabling industrial organizations to no longer have to rely exclusively on conventional material subtraction techniques such as milling or turning. 3D printing and sustainability thus form a perfect pairing that also reduces material waste in production processes.

Circular economy

And if we talk about material waste, the circular economy in industry is one of the most relevant issues for companies operating in this sector. Any production process involves an environmental impact and costs, and the objective of the circular economy is to reduce both.

The key to implementing an effective circular economy is to develop strategies that maximize the durability, reuse, repair and recycling of products and materials. With the use of tools that enable product life cycle analysis, it is possible to develop cleaner manufacturing and design products with a reduced carbon footprint that can be effectively recycled once their life cycle is over.

Últimos posts

aggity strengthens its commitment to sustainability as a SILVER partner of “Fundación Empresa & Clima”.

aggity participates in the IBM Ecosystem Summit 2024 with an applied case of Generative AI in the food industry

Aggity, together with the multinational Fortinet, present an exclusive event in Lima on the application of Generative AI in Corporate Cybersecurity.

aggity participates in Smart Ports: Piers of the Future

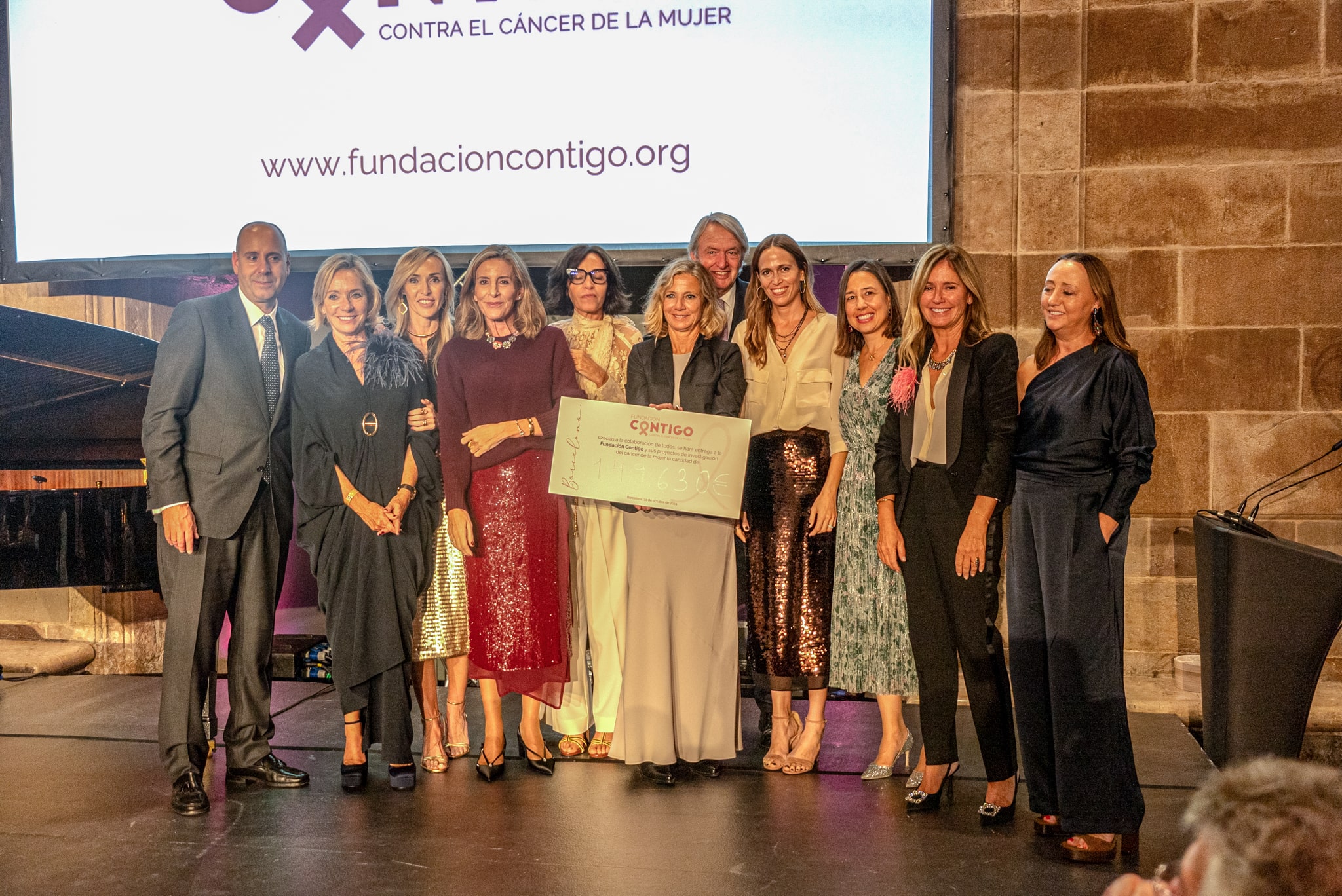

aggity Supports the Contigo Foundation at its Annual Dinner

Challenges and Opportunities of Generative AI in Industry: Our Experience at BNEW

Official Liferay Partner in Spain