Characteristics of Automation in the Smart Factory

Automation in the Smart Factory is a cornerstone of digitalization in industrial companies. This article explores the defining characteristics of this revolution: from operational efficiency to improved quality, automation is shaping the future of manufacturing.

Tabla de contenidos

ToggleExplore the key features of automation in a Smart Factory.

This is not a new concept, as automation has long driven operational efficiency in industrial environments. However, the features of automation in the Smart Factory are making innovation in manufacturing in industrial environments much faster.

This is because the Smart Factory is benefiting from the incorporation of different technologies that achieve efficient processes, improved product quality and resource optimization. Technologies such as industrial robotics, the Internet of Things (IoT), systems integration or the different types of industrial automation are types of industrial automation that are enabling a very rapid evolution that has not been seen since the beginning of the first industrial revolution.

Automation in the Smart Factory has, therefore, different characteristics that make it different from other processes of the past. Some of these keys are as follows:

Operational efficiency

One of the most salient features of automation in the Smart Factory is the ability it has to drive operational efficiency to previously unseen levels. Automated production allows the execution of the most repetitive tasks. This minimizes errors and drastically reduces downtime because automated control systems ensure that operations run consistently, leading to higher productivity and reduced production variability.

Flexibility and adaptability

Flexibility and adaptability are two of the fundamental characteristics in the technological innovation of the Smart Factory and have turned it into a model that allows, for example, improving the supply chain or obtaining cost reductions. Thanks to the flexibility provided by automation, factories can adjust and adapt to changes in production, so that production volumes can be altered or even the design of a product can be changed easily and efficiently.

If flexibility is important, adaptability will play an increasingly important role. Solutions such as Smart Factory by aggity, which incorporates machine learning and artificial intelligence technology, enable companies to analyze data in real time to identify production problems and prevent losses, predict machine failures and optimize processes on an ongoing basis. This achieves excellence in intelligent manufacturing.

By being able to run real-time monitoring, the production process means analyzing and presenting production data in order to have a detailed view.

Error reduction

In traditional industrial environments, human error is common. With the adoption of automation, these errors virtually disappear. This is one of the key characteristics of industrialization 4.0, as automated systems can perform repetitive, high-precision tasks without fatigue or errors, resulting in improved product quality and increased productivity.

Automation also minimizes the need for quality control and production problem management resources, leading to significant cost savings.

Improved security

Finally, another of the most important Smart Factory automation features has to do with safety. One of the most obvious benefits is the reduction of workers’ exposure to occupational hazards as those more dangerous tasks can be performed by robots, so that the employee does not have to deal with potentially dangerous work and can focus on tasks of greater value to the companies.

Últimos posts

aggity strengthens its commitment to sustainability as a SILVER partner of “Fundación Empresa & Clima”.

aggity participates in the IBM Ecosystem Summit 2024 with an applied case of Generative AI in the food industry

Aggity, together with the multinational Fortinet, present an exclusive event in Lima on the application of Generative AI in Corporate Cybersecurity.

aggity participates in Smart Ports: Piers of the Future

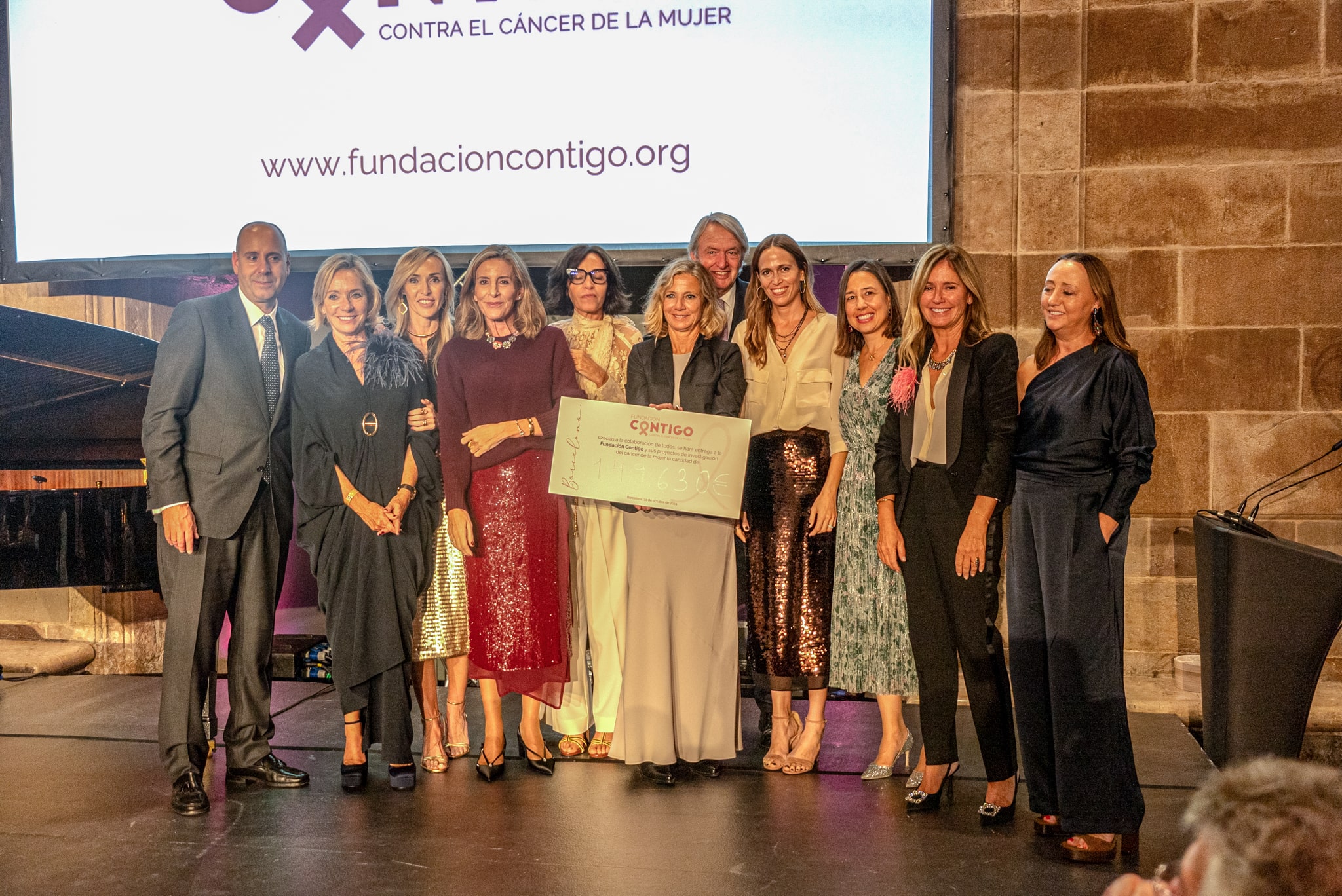

aggity Supports the Contigo Foundation at its Annual Dinner

Challenges and Opportunities of Generative AI in Industry: Our Experience at BNEW

Official Liferay Partner in Spain