Industrial Robotics in the Smart Factory

Industrial robotics is transforming factory operations. However, although it seems that the transformation of the industry is recent, the road to the smart factory started years ago. In this article we take a closer look at this revolution and how it drives production efficiency.

Tabla de contenidos

ToggleDiscover how industrial robotics is revolutionizing the Smart Factory. Explore examples and benefits of this technology.

Industrial robotics in Smart Factories represents an opportunity that companies are taking advantage of to drive innovation, improve product quality and thus become much more competitive organizations. We find ourselves in a new era which, thanks to the automation of industrial processesthe use of the so-called Industrial Internet of Things (IIoT) or the use of tools that allow the digitization of production are making us face a more important Industrial Revolution than the one that took place at the end of the 18th century.

Industrial Robotics in the Smart Factory

The history of industrial robotics dates back to the 1950s when the first industrial robots designed for very simple tasks such as welding began to be developed. From that moment on, the first programmable robots began to be developed and it was in the 70’s when the first machines that allowed the automation of manufacturing began to be implemented.

Today, the role of robots in the production smart factory and in the Industry 4.0 has come a long way thanks to the incorporation of the so-called cobots (collaborative robots) and advanced robotics, with robots incorporating technologies such as artificial intelligence to improve the production efficiency o that allow adapting to changing production conditions to speed up decision making.

Industrial robotics applications

There are numerous uses of industrial robotics by companies in different production sectors. One of the most common is the automation of assembly lines. In this example, robots perform repetitive tasks, such as the assembly of components or parts, in a precise manner that increases production speed and improves product quality.

The same is true for the use of robots for material handling and transport. Mostly used in the food industry, in this case the robots are in charge of packaging the products, which translates into an optimization of the supply chain. supply chain optimization delivery processes can be accelerated.

The applications of industrial robotics go beyond that. Some of its applications have to do with automation and quality control in such a way that robots, equipped with cameras and sensors, are able to examine products for defects. It is typically used in industries with advanced manufacturing technology such as electronics or medical device manufacturing.

Undoubtedly, one of the sectors in which industrial robotics is having the greatest impact is the medical sector, where robotic surgery allows less invasive and less dangerous operations to be performed on patients.

Enabling technologies

There are different technologies and solutions that favor robotics and automation to end up in the integration of production systems in any company. Thanks to the use of technologies such as Artificial Intelligence or big data, a solution such as Smart Factory by aggity allows to know the real situation of a Smart Factory. This type of tool can perform predictive maintenance on equipment, enable more effective warehouse automation or improve energy efficiency in production. energy efficiency in production by knowing precisely when, for example, a peak in demand is going to occur.

Artificial intelligence and machine learning in robotics allow robots not only to perform programmed tasks, but also to learn, adapt to changing situations in real time and make decisions to, for example, improve the productivity of a given machine at a specific time.

Últimos posts

aggity strengthens its commitment to sustainability as a SILVER partner of “Fundación Empresa & Clima”.

aggity participates in the IBM Ecosystem Summit 2024 with an applied case of Generative AI in the food industry

Aggity, together with the multinational Fortinet, present an exclusive event in Lima on the application of Generative AI in Corporate Cybersecurity.

aggity participates in Smart Ports: Piers of the Future

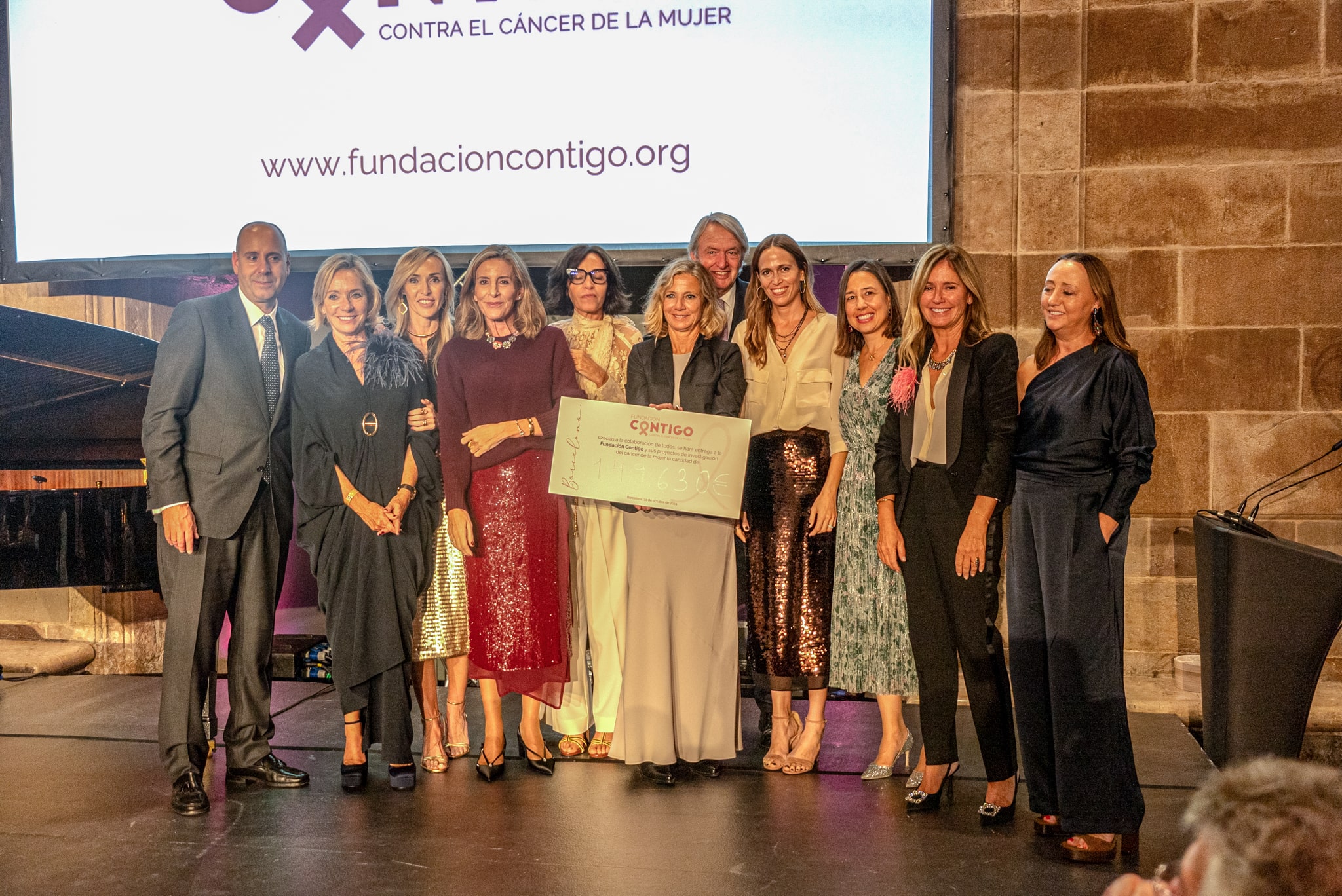

aggity Supports the Contigo Foundation at its Annual Dinner

Challenges and Opportunities of Generative AI in Industry: Our Experience at BNEW

Official Liferay Partner in Spain