Collaborative robots in industry 5.0

When industrial organizations are still immersed in applying and extending the processes of the so-called Industry 4.0, some companies are already taking steps in the next evolution which is Industry 5.0, where collaborative robots are going to play a prominent role.

Tabla de contenidos

ToggleCollaborative robots are capable of doing any type of manual or repetitive work, but above all they are being used to reduce risks to workers.

The difference between Industry 4.0 and Industry 5.0 lies precisely in the human factor. Industry 4.0 involves the digital transformation of traditional tasks with the implementation of techniques to improve production and that, in general involves the incorporation of technologies such as robotics, analytics, automation solutions and also the IoT or Internet of Things. Industry 5.0 continues to employ all of these technologies, but it is all about bridging the relationship that occurs between machines and humans. To this end, Artificial Intelligence is going to play a key role with the intention that cobots or collaborative robots perform processes that execute the thinking of a person.

What is a collaborative robot

Robots are one of the keys to Industry 5.0. In this case, when we refer to a cobot, we are talking about a robot that has been designed to work together with humans. In other words, unlike traditional industrial robots, cobots interact with humans and assist them in different tasks and processes. In other words, the cobot cannot function if there is no person at its side and vice versa. This is a perfect collaborative model.

Collaborative robots are capable of doing any type of manual or repetitive work, but above all they are being used to reduce the risks that workers in industrial environments may suffer, thus reducing the possibility that they may suffer an accident at work.

But if there is a differentiating aspect in the use of this type of robots in Industry 5.0 , it is to meet one of the main objectives of this new industrial revolution: to make organizations more human and attractive to workers.

The role of the collaborative robot

In an Industry 5.0 and smart factory environment, the aim is for humans to benefit from the possibilities and advantages offered by collaborative robots, such as their technical precision or their ability to lift very heavy material. On the other hand, workers can dedicate themselves to more complex tasks, giving industrial companies a greater degree of control and the ability to individualize each phase of production.

Through the use of a collaborative robot, an organization can have greater potential for customization which, unlike automated Industry 4.0 systems, will enable greater job creation.

The use of cobots in industry will radically transform industrial environments. Whereas up to now they have worked independently, in an Industry 5.0 environment, robots and humans work in unison. We will no longer see those spaces in which, even in the same physical space or on the same production line, you could see the robot on one side and the person on the other, working independently.

Collaborative human-robot working together

With Industry 5.0, that demarcation becomes more blurred as humans and robots begin to work together, such that the cobot will perform lower-value work and humans will provide the skills that the collaborative robot is incapable of performing. Solutions such as Smart Factory by aggity already allow to digitize the factory thanks to a perfect and complete automation of processes and prediction of actions and, soon, collaborative robots will improve all these processes.

Industry 5.0 will enable more sustainable development and drive the creation of much more customized products tailored to individual needs. Sectors such as healthcare or the pharmaceutical industry will benefit significantly from this collaboration between humans and collaborative robots.

Últimos posts

aggity strengthens its commitment to sustainability as a SILVER partner of “Fundación Empresa & Clima”.

aggity participates in the IBM Ecosystem Summit 2024 with an applied case of Generative AI in the food industry

Aggity, together with the multinational Fortinet, present an exclusive event in Lima on the application of Generative AI in Corporate Cybersecurity.

aggity participates in Smart Ports: Piers of the Future

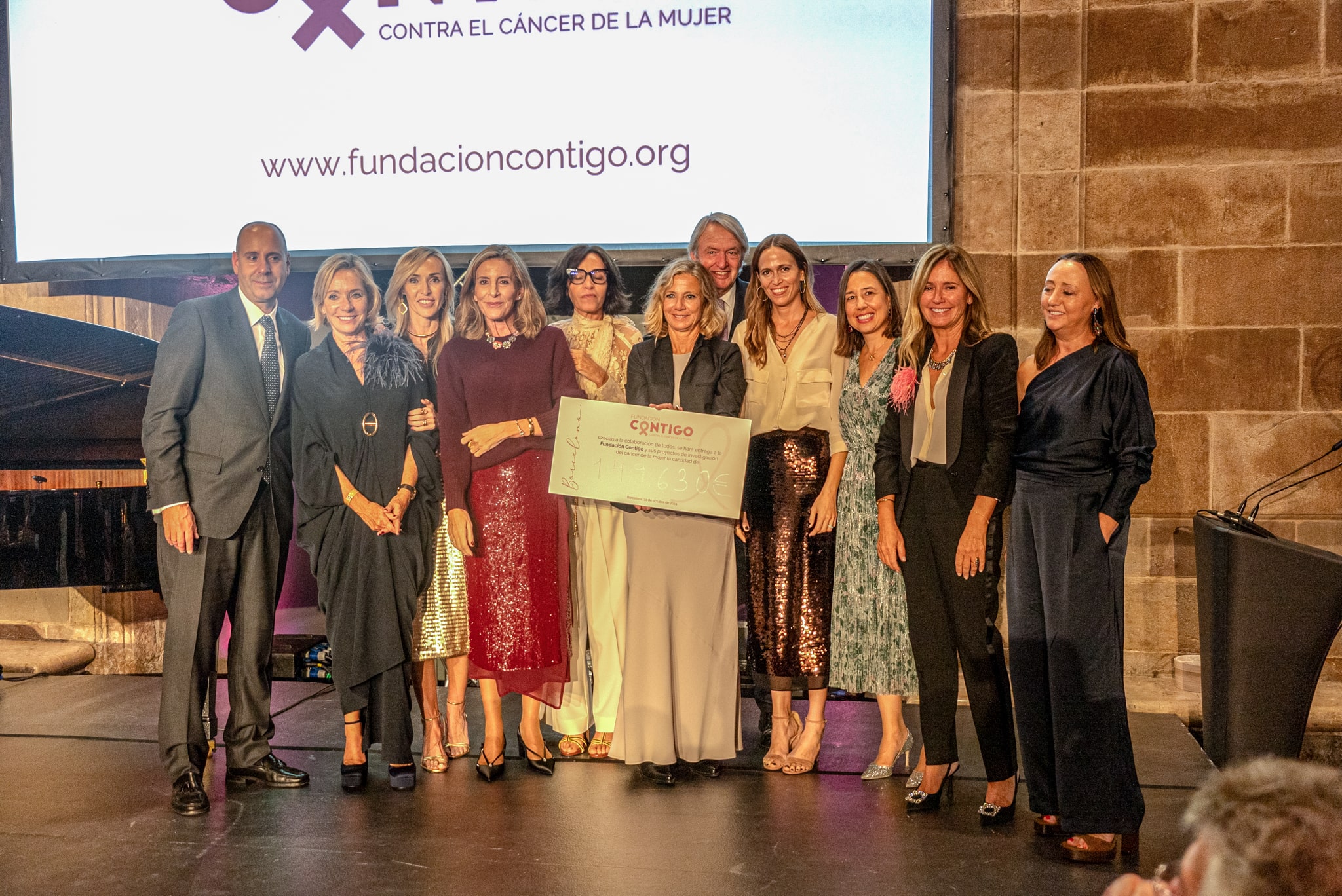

aggity Supports the Contigo Foundation at its Annual Dinner

Challenges and Opportunities of Generative AI in Industry: Our Experience at BNEW

Official Liferay Partner in Spain