MES systems: a global monitoring of Industry 4.0

Tabla de contenidos

ToggleMES systems automatically monitor, store and trace all activity performed by factory operators, providing detailed information about WHO did the activity, WHAT they did, WHERE it took place and WHEN it was performed.

The Haystack Syndrome

Maria, the production manager, and Juan, the factory manager, do not have an overview of what is going on “downstairs” for some time, and up-to-date information is conspicuous by its absence. They do not know the detailed status of the progress of the production plan at all times, so it is impossible for them to answer questions to the sales team such as: “Customer ABC is asking me if order 123456 will be delivered on the 3rd of next month, as agreed”.

The absence of truly reliable information on the time spent on product and format changeovers, cleaning, micro-stops and losses due to low machine speed prevents the implementation of continuous improvement policies.

Other factory or production managers do have information, but they have it in very inflexible Excel formats for analysis and, above all, it is not available to be shared with the team at any time.

Juan and Maria have realized that they have thousands of data, but when it comes down to it, they cannot find the information that is really relevant for decision making, which prevents them from knowing exactly what is really going on in the factory. They don’t know it, but they suffer from the so-called “haystack syndrome”. Having millions of DATA is NOT RELEVANT INFORMATION.

Maria often discovers that a level of product rejection is occurring, which is out of control due to a lack of real-time information. When this happens, it is too late, the product is not usable.

In trying to organize improvement actions, Maria realizes that, lacking reliable information, she has not asked the operators about their problems, nor has she given them feedback on how things are going. In short, it has not involved them in the detection and solution of problems… it is a fish that bites its own tail.

MES systems or software: What are they and what do they do?

A smart factory or factory 4.0 has a system that captures data from production and other manufacturing areas such as maintenance, quality, logistics and planning, crosses them and generates relevant information that helps to make decisions in the short, medium and long term, and with a multidisciplinary vision (a factory is not only production). These systems are known as MES systems or Software MES (Manufacturing Execution System).

From a strictly production point of view, every MES system:

- Collects data automatically.

- Details machine stoppages and reasons for rejected product.

- Allows paperless management of the entire factory.

- It shows the realized and pending production in real time, allowing to know how is the production plan at any time and from any place.

- Analyzes productivity and resource efficiency.

- Provides reports for short-, medium- and long-term production management.

- Plots direct and indirect activities, justified machine stoppages, preparations, quantities produced, rejects according to type, rework.

- Monitor resources and consumption in real time.

- It has real-time dashboards (operator, machine, OF…).

- Enables workload histograms for each machine.

- Generates interactive maps of factory, department, area or work center, showing the status of the machines at all times.

- MES systems automatically monitor, store and trace all activity performed by factory operators, providing detailed information about WHO did the activity, WHAT they did, WHERE it took place and WHEN it was performed.

- INDUSTRY 4.0 is synonymous with INTERCONNECTIVITY between machines, things, people, systems, processes, and other actors such as customers, suppliers or other types of collaborators.

- MES solutions are at the heart of all connectivity if the production process is to be oriented towards the smart factory, and are the management solution par excellence for shift managers, area managers, factory managers and industrial managers.

Written by David Fernández

Industry Area Manager at aggity

Últimos posts

aggity strengthens its commitment to sustainability as a SILVER partner of “Fundación Empresa & Clima”.

aggity participates in the IBM Ecosystem Summit 2024 with an applied case of Generative AI in the food industry

Aggity, together with the multinational Fortinet, present an exclusive event in Lima on the application of Generative AI in Corporate Cybersecurity.

aggity participates in Smart Ports: Piers of the Future

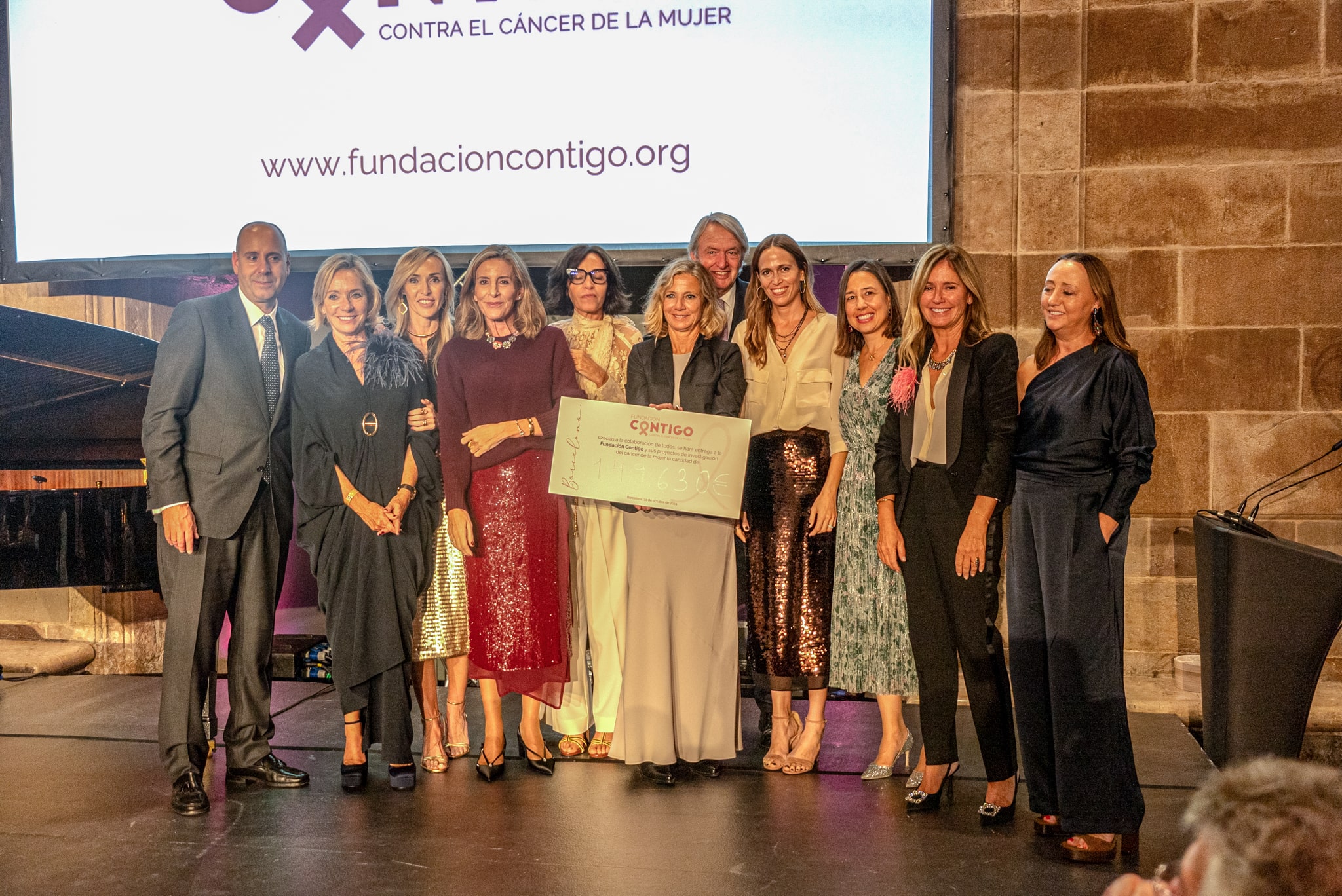

aggity Supports the Contigo Foundation at its Annual Dinner

Challenges and Opportunities of Generative AI in Industry: Our Experience at BNEW

Official Liferay Partner in Spain