To the classic challenges of profitability, efficiency and effectiveness, the Industrial sector now adds the challenge of decarbonization and digital transformation plays a key role in responding to it.

Profitable and Sustainable Industry 4.0

aggity’s platform integrates proprietary and third-party modular solutions to meet the needs of the industrial sector in the face of the challenge of Sustainable Industry 4.0.

Our Planning (APS) and Execution (MES / MOM) solutions integrated with Energy Management (EMS), Advanced Analytics Platform (AI & Analytics Factory) and Asset Management (EAM / CMMS) enable industrial organizations to meet the challenges of the 21st century.

The technological disruption experienced in recent years has facilitated access to a series of tools that until recently seemed within the reach of only a few companies, but which can now form part of the present of any organization.

Our solutions respond to the Planning, Execution, Improvement and Decarbonization needs of Industrial Organizations in all sectors.

Planning

of the production

PlanetTogether by aggity is a production planning / sequencing software that seamlessly covers the development of a production plan for a manufacturing company. From Master Production Plan (MPS) and Material Planning (MRP) to Plant Sequencing.

Plans and schedules production based on available materials, labor, machine capacity and optimal sequencing, according to changeover times.

Main functionalities

- Planning and scheduling at finite capacity

- Management of links between orders, pegging of materials

- Primary and secondary resource management

- Attribute management and setup matrices

- Push-Pull Planning (ASAP – JIT)

- Visual Scheduling

- Graphical and interactive Gantt chart

- Planning and scheduling at finite capacity

- Management of links between orders, pegging of materials

- Primary and secondary resource management

- Attribute management and setup matrices

- Push-Pull Planning (ASAP – JIT)

- Visual Scheduling

- Graphical and interactive Gantt chart

- Histogram of resource workloads

- Unattended automatic scheduling

- Multi-user collaboration

- What-if analysis

- Optimization rules (Delivery-Productivity)

- Analysis and KPIs

PLANNING

When is a planning tool essential?

Excel

Few references

On-line process

Few operations

Few customers

Few changes

Error-free plan

Relaxed planner

On-time deliveries

Advanced Planner (APS)

Many references

Organization by sections

Many operations

Many customers

Typical changes

Plan with errors

Stressed planner

Delays

Planning

of the production

PlanetTogether by aggity is a production planning / sequencing software that seamlessly covers the development of a production plan for a manufacturing company. From Master Production Plan (MPS) and Material Planning (MRP) to Plant Sequencing.

Plans and schedules production based on available materials, labor, machine capacity and optimal sequencing, according to changeover times.

Operations

- Increases effective capacity by reducing changeover times for higher performance

- Achieves reliable and on-time delivery while reducing lead times and WIP inventory

- Improves visibility and capacity utilization: simply adjust the “optimization rules” to drive business goals

Planner Scheduler

- Keeping the plan up to date with planning changes will be much easier when you have the right tool

- Gantt charts and automatic drag-and-drop function make reprogramming visual and intuitive

- Respond to scheduling change requests with clear information about the impact on the customer and minimize counterproductive rescheduling

Supply Chain

- Synchronizing purchasing with production to reduce material costs

- Achieves reliable and on-time delivery while reducing lead times and WIP inventory

- Gain early visibility of material requirements to avoid last-minute supply chain disruptions

Management of the

production

An MES / MOM System is a complete, modern, configurable and modular MES (or plant control) industrial management software that perfectly covers the management and control of Production, Quality, Materials and Maintenance activities, as well as the communication with machines and plant devices (PLCs, scales, scanners, etc.). Fully integrable with any ERP.

The MES system integrates the Production Management modules for the creation, launching and tracking of Work Orders in the plant. Capture of progress and efficiency information in the plant. Materials and Traceability for the connection of warehouses and supplies with production flows in the plant, as well as traceability of material usage. Quality for process and product control synchronized with ongoing production. Maintenance to ensure efficient and effective asset repair.

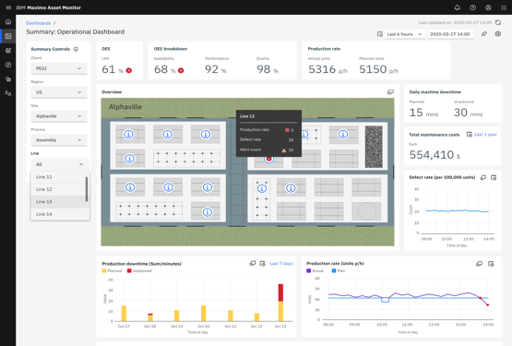

It includes a module of indicators for each of the functionalities with the main KPIs for production optimization (OEE, Availability, Performance, Quality Factor, Material Shrinkage, Product and Process Quality, MTBF, MTR, etc.).

Planner Scheduler

- Opera MES offers an easy, intuitive and modern graphical interface to production operators.

- Native and easy communication with plant devices (Machines, sensors, scales, IR readers, PLCs)

- Real-time plant information

- Opera MES offers an easy, intuitive and modern graphical interface to production operators.

- Native and easy communication with plant devices (Machines, sensors, scales, IR readers, PLCs)

- Real-time plant information

- Automatic OEE calculation (availability, performance, quality)

- Operators can report Downtime or Shortage Reasons to analyze and apply continuous improvement

- Modules for Production, Materials, Quality, Traceability, Maintenance and Connection with Machines / devices.

- Automatic OEE calculation (availability, performance, quality)

- Operators can report Downtime or Shortage Reasons to analyze and apply continuous improvement

- Modules for Production, Materials, Quality, Traceability, Maintenance and Connection with Machines / devices.

Analytics

advanced

Solution for Advanced Analytics on the plant floor, AI & Analytics Factory, offers a solution for descriptive and predictive analytics on the most common platforms in the market (Power Bi, Azure IoT / ML, AWS). Some of the examples of solutions we offer are:

- Demand forecasting

- Predictive maintenance

- Minimum viable product

- Demand forecasting

- Predictive maintenance

- Minimum viable product

- Quality 0 defects

- Cause – root cause of production problems

- Quality 0 defects

- Cause – root cause of production problems

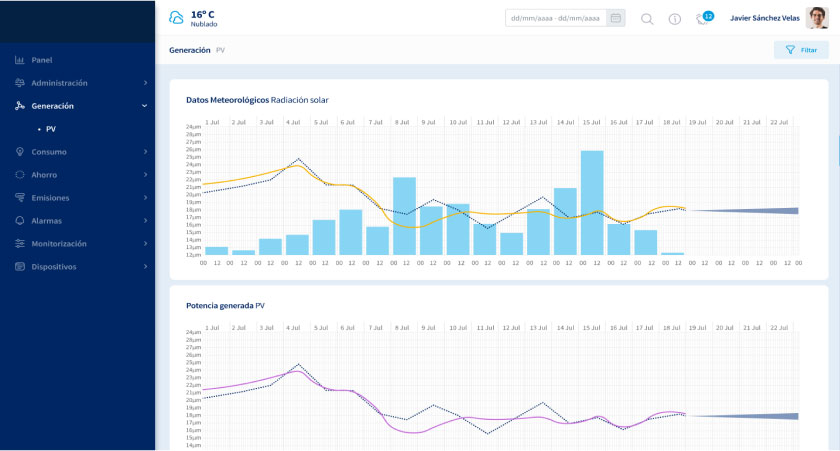

Proprietary IoT Platform

The IoT platform allows to connect to devices / machines, store sensor values, visualize them in real time and history, display alarms and warnings, as well as perform all associated management.

Asset management

EAM / CMMS

Ensuring maximum availability of the critical assets of industrial companies (machines), as well as reducing operational costs are some of the benefits of asset management platforms (EAM) or maintenance management (CMMS).

Why digitize

plant maintenance?

The asset management cloud platform allows standardizing maintenance processes and procedures, as well as making all asset information and documentation available to maintenance personnel.

Contact one of

our experts

to advise you in the development of a Digitalization Plan that responds to the real needs of your organization.

Click here and one of our specialists will contact you to arrange a meeting. Because talking about advantages is easy… but demonstrating them is another matter.

Success stories

COMMITMENT

They trust us

LET’S TALK

Do you have a project?

Contact us today to discuss your project. We are committed to providing innovative solutions that propel your company into the future. Together we can bring your vision to life!