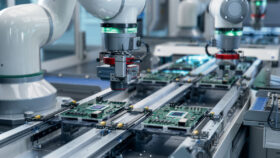

Types of Industrial Automation in the Smart Factory

In the era of Industry 4.0, automation has become one of the pivotal elements of any production plant’s strategy as it streamlines processes, improves efficiency and reduces costs.

Tabla de contenidos

ToggleExplore with aggity the types of industrial automation crucial for a successful Smart Factory.

There are different types of industrial automation, each with different technologies and approaches. From robots and CNC machines to process control systems, automation covers a wide range of applications. For this reason, choosing the right type of industrial automation is crucial to meet the specific needs of each smart factory.

In the same way that the way a factory in the food sector works is not the same as one in the automotive sector, the automation needs to be covered are also different. In this article, we will explore the main types of industrial automation and how they can revolutionize modern production.

Fixed or rigid automation

It is one of the oldest types of industrial automation used in production lines. We are talking about one of the key elements in the optimization of processes in industrial organizations. Fixed automation has been used for decades in a variety of industries, from manufacturing to logistics to automated supply chain.

It consists of programming machines or systems to perform a predetermined sequence of steps, generally in a linear and sequential flow. It is a very effective technology when processes are standard and do not require constant adaptation. Its main advantage is reliability, which ensures that human error is reduced to a minimum.

Programmable automation

In this case, it is an advanced form of automation that offers greater flexibility and adaptability compared to fixed or rigid automation. In programmable automation, the control systems or industrial robotics elements of a smart factory are programmed to perform specific tasks, but, unlike the previous one, it has the ability to modify their behavior to to adjust to changing conditions or unforeseen situations. .

Flexible automation

Flexible automation goes one step further. While programmable automation relies on predefined instructions, flexible automation leverages Artificial Intelligence (AI) and machine learning to adapt and respond to new conditions and scenarios in real time.

This type of industrial automation is primarily used in factories that experience variable workflows or require interaction with unstructured data. To adapt manufacturing processes and improve production efficiency. One example is collaborative robots or cobots.

Flexible automation tends to be confused with adaptive automation, but the latter has the ability to adapt to changes in the environment or production process automatically and without the need for human intervention.

Process control automation

This typology focuses on improving efficiency, product quality or adjusting the use of materials to obtain cost reductions. To this end, it employs automated systems, industrial sensors and other elements such as the Internet of Things (IoT) that enable the monitoring and optimization of processes in order to reduce human intervention and minimize errors.

In this regard, a market benchmark solution such as PlanetTogether by aggity enables finite capacity planning and scheduling of production activities, taking into account the availability of resources and materials.

One of the components of process control automation is Computer Numerical Control (CNC) , which allows components and parts to be produced faster, more accurately and cost-effectively.

Robotic automation

Also known as robotic process automation or RPA, it employs software robots to automate repetitive tasks that interact with systems and applications in the same way a user would, but with greater speed and accuracy.

Robotic process automation is commonly used in business environments where many manual and routine tasks are performed, such as data entry, reporting and data reconciliation. One of the many benefits of RPA is that it frees employees from this type of work, allowing them to focus on other, higher-value work.

Other types of industrial automation

There are other types of automation that, in combination with different manufacturing technologies, aim to continuously improve production efficiency. These include, among others, assembly automation, for the assembly of parts; warehouse automation, to optimize storage; or inspection and testing automation, to assess product quality.

Últimos posts

aggity strengthens its commitment to sustainability as a SILVER partner of “Fundación Empresa & Clima”.

aggity participates in the IBM Ecosystem Summit 2024 with an applied case of Generative AI in the food industry

Aggity, together with the multinational Fortinet, present an exclusive event in Lima on the application of Generative AI in Corporate Cybersecurity.

aggity participates in Smart Ports: Piers of the Future

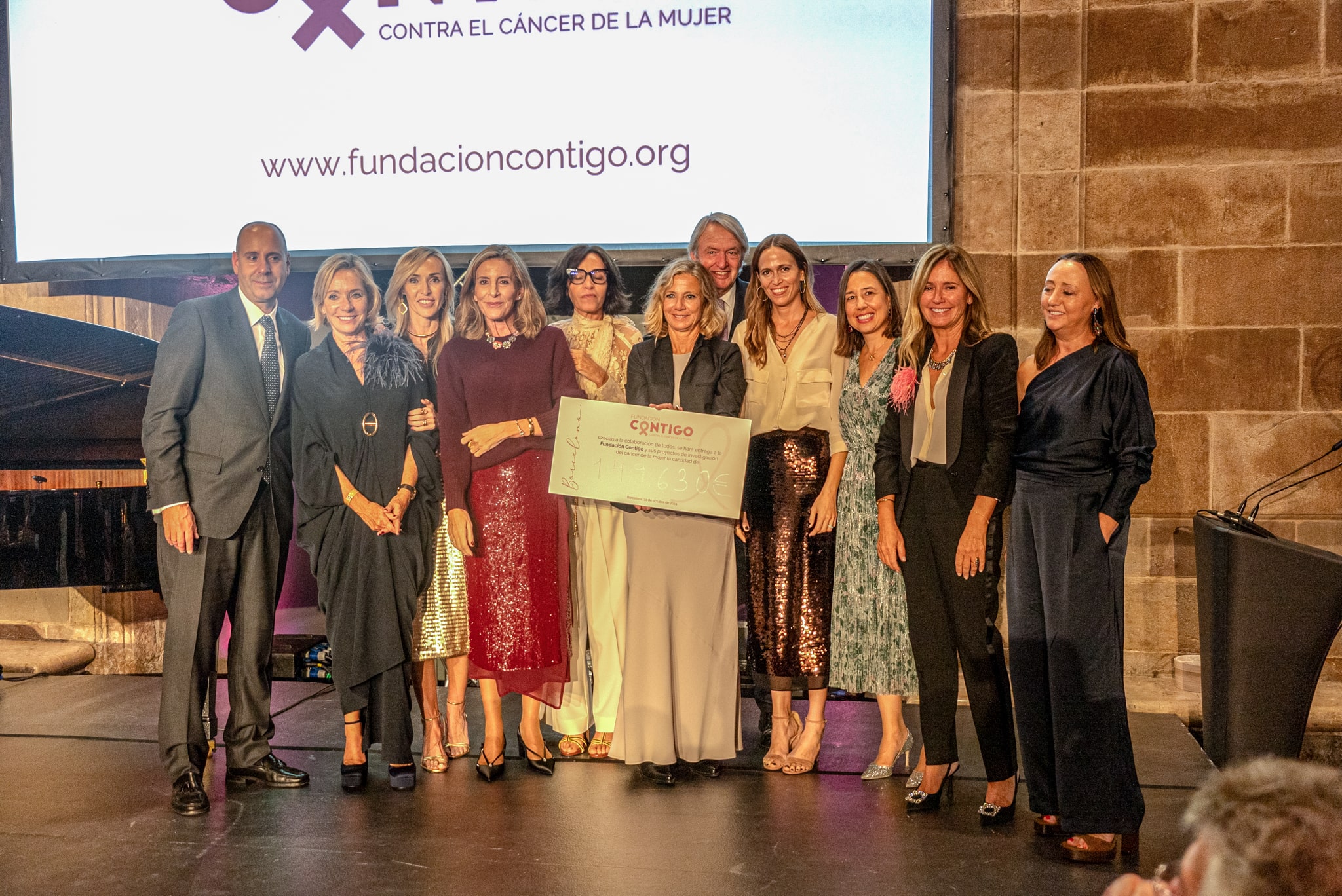

aggity Supports the Contigo Foundation at its Annual Dinner

Challenges and Opportunities of Generative AI in Industry: Our Experience at BNEW

Official Liferay Partner in Spain