EMS: the ally for a sustainable factory

Environmental Management Systems (EMS) are essential to make factory operations more sustainable and efficient. A well-implemented EMS is a transformational change for production plants.

Tabla de contenidos

ToggleExplore how environmental management systems (EMS) can help make production more sustainable and efficient; find out the keys here.

The environmental management systems o SGA are not merely a new technology, although they benefit from it, but a comprehensive management philosophy that seeks the optimization of natural resources such as energy, water and raw materials; to improve the industrial waste management and pollutant emissions; to prevent environmental accidents or to increase the energy efficiency in industry.

One of the great advantages of EMSs is that they can be integrated into a plant’s daily operations, examining success stories and providing practical recommendations. In this article we will discuss how to maximize process efficiency and sustainability through the use of EMS.

Environmental policy

The development of policies to improve corporate sustainability is one of the areas where EMS environmental management systems can help. These systems provide clear guidelines and internationally recognized standards, such as ISO 14001, which serve as the basis for sound environmental policies.

At this point, the communication of these policies across all divisions of the organization is important because it ensures that the implementation of eco-efficient strategies for the industry is successful.

Planning

The first step in integrating corporate sustainability into the smart factory is to understand the impact its activities have on the environment. EMSs are used to plan, identify and evaluate the environmental aspects of industrial operations. From resource consumption to waste generation management or product life cycle analysis, EMSs enable companies in the industrial sector to understand how their actions affect the environment.

Legal compliance

The area of environmental legality and compliance is one of the areas in which EMS environmental management systems stand out, as they provide a structured framework for identifying and understanding the legal obligations that affect the smart factory in relation to the environment. This includes laws on waste management, carbon footprint reduction and carbon footprint reduction, or resource conservation. carbon footprint or resource conservation.

Training and awareness

Train and sensitize all employees on environmental practices and their role in the EMS. At the same time, environmental management systems facilitate employee training and awareness by providing a structured framework for the implementation of environmental education programs.

Operational control

EMSs help to have control of daily activities that can have an impact on the environment. This control makes it possible to know what clean production technologies are being used or how to improve eco-innovation in production.

Operational control allows the implementation of practical measures and procedures to manage the environmental aspects identified during initial planning. This may include the adoption of cleaner and more efficient work practices, the implementation of solutions such as Planet Together by aggity that help to establish eco-efficient strategies for industryoptimize the resources used in the production processes or that help the company’s emission reduction in manufacturing.

Monitoring and measurement

The establishment of a sustainability policy is a continuous process of improvement. EMSs allow environmental monitoring and reporting to analyze the company’s environmental performance.

Using the data and subsequent analysis, companies can identify areas for improvement and adjust their policies and procedures as necessary to ensure their effectiveness over time. Monitoring must be continuous as it is the only way to identify opportunities for improvement in corporate environmental responsibility.

Auditing and continuous improvement

Conducting an environmental audit to ensure compliance with the EMS and continually seeking opportunities to improve the organization’s environmental performance should be a priority for companies.

These types of reports not only seek to ensure compliance with environmental laws, but are also useful for measuring progress in achieving environmental objectives or identifying areas for improvement to optimize environmental performance.

Últimos posts

aggity strengthens its commitment to sustainability as a SILVER partner of “Fundación Empresa & Clima”.

aggity participates in the IBM Ecosystem Summit 2024 with an applied case of Generative AI in the food industry

Aggity, together with the multinational Fortinet, present an exclusive event in Lima on the application of Generative AI in Corporate Cybersecurity.

aggity participates in Smart Ports: Piers of the Future

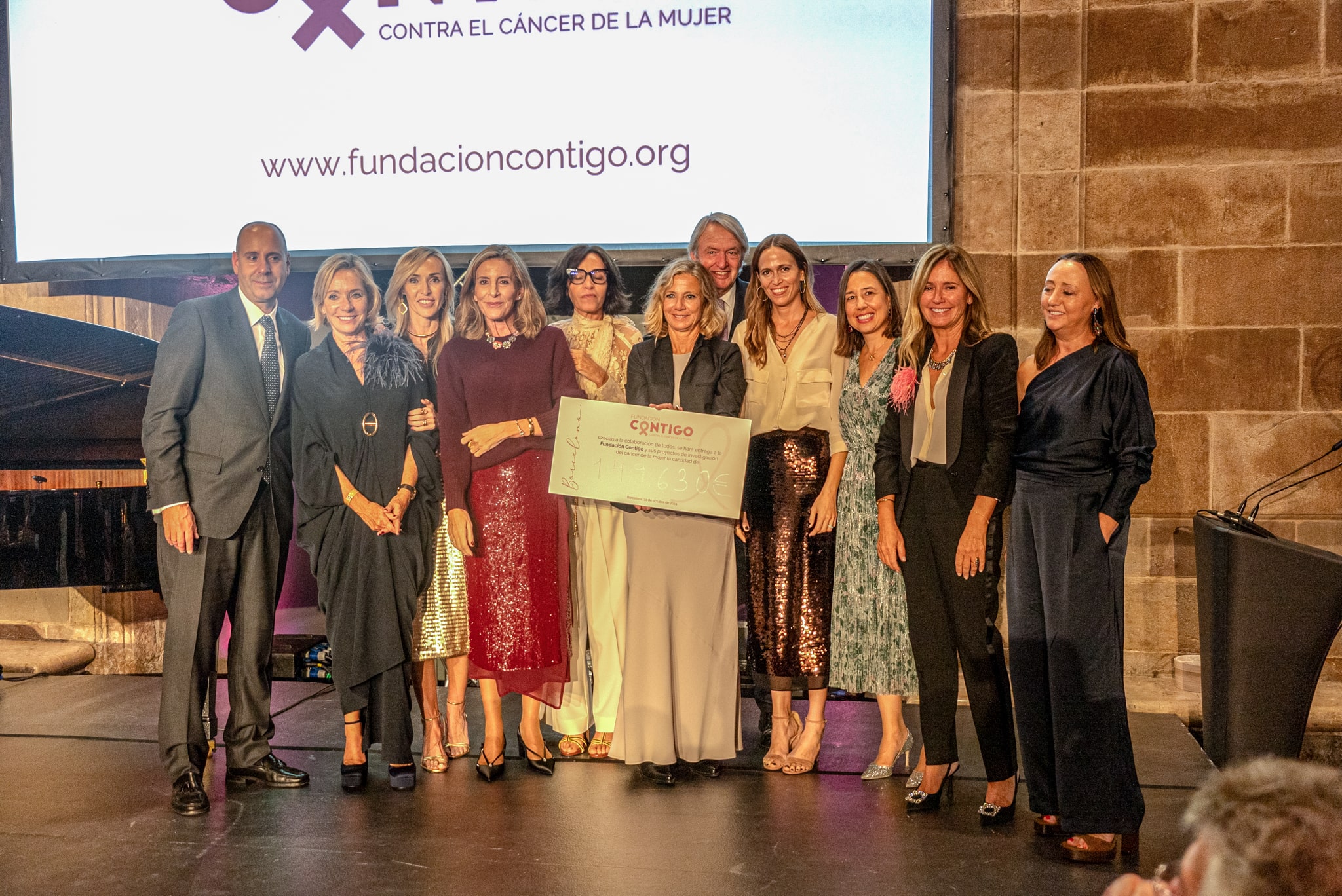

aggity Supports the Contigo Foundation at its Annual Dinner

Challenges and Opportunities of Generative AI in Industry: Our Experience at BNEW

Official Liferay Partner in Spain