Examples of Machine Learning in Smart Factories

From predictive maintenance to supply chain optimization. In this article we will explore examples of how machine learning technology is being successfully implemented in plant and production environments, providing efficiency and competitive advantages.

Tabla de contenidos

ToggleExplore real-world examples of how Machine Learning transforms Smart Factories.

The integration of Machine Learning or, in other words, machine learning, in the so-called Smart Factories is one of the most important elements in this new industrial revolution known as Industry 4.0. The vast majority of the uses of machine learning in industry have to do with elements such as the production optimizationThe use of machine learning algorithms makes it possible to analyze data in real time in order to adjust production speed, manage inventories and manage the quality of the product. avoid losses in the industry.

In addition, smart factories use machine learning as an element to execute the predictive maintenance . The way it works is based on the installation of sensors in the machines of a factory and that are responsible for collecting data on the operation of these. In this way, anomalous patterns can be identified, allowing maintenance intervention to be scheduled before the machine fails, reducing unplanned downtime and costs.

Automation

The use of machine learning is usually associated with the implementation of automation processes in smart factories. Thanks to this, it is the machines themselves that can adapt automatically and without the need for human intervention to any peaks in demand that may occur. Of course, machine learning also plays a key role in supply chain optimization and efficiency. optimization and efficiency in the supply chain because, with its use, smart factories can analyze historical supply chain data, as well as real-time data, to predict the demand for raw materials and components.

Among other technologies, the Smart Factory by aggity platform employs machine learning to improve manufacturing innovation, manage and perform predictive maintenance of all its equipment. The following are examples of machine learning that are already being implemented in industrial companies.

Siemens

Siemens is employing machine learning to execute a digital transformation in total manufacturing. That change has involved processes ranging from product design to supply chain management. In doing so, the German giant has achieved a number of significant improvements in the efficiency and quality of its products.

General Electric (GE)

The North American multinational has adopted machine learning in its manufacturing division to perform real-time predictive maintenance on its machines and equipment. This has significantly reduced maintenance costs and prevented unplanned downtime.

Bosch

A clear example of what data analytics provides in the manufacturing industry can be found in the German firm Bosch, which uses machine learning and the data it provides to improve the quality and efficiency of manufacturing processes. This has not only saved costs, but also significantly improved production.

Whirlpool

Another clear example of predictive maintenance is that of appliance manufacturer Whirlpool, which uses machine learning on its production lines to predict and prevent product defects. This has improved quality and reduced warranty costs.

Valeo

Another example of machine learning can be found in this automotive components company, which in this case uses it for the quality inspection of its products. With this, the company has achieved greater accuracy in defect detection.

Últimos posts

aggity strengthens its commitment to sustainability as a SILVER partner of “Fundación Empresa & Clima”.

aggity participates in the IBM Ecosystem Summit 2024 with an applied case of Generative AI in the food industry

Aggity, together with the multinational Fortinet, present an exclusive event in Lima on the application of Generative AI in Corporate Cybersecurity.

aggity participates in Smart Ports: Piers of the Future

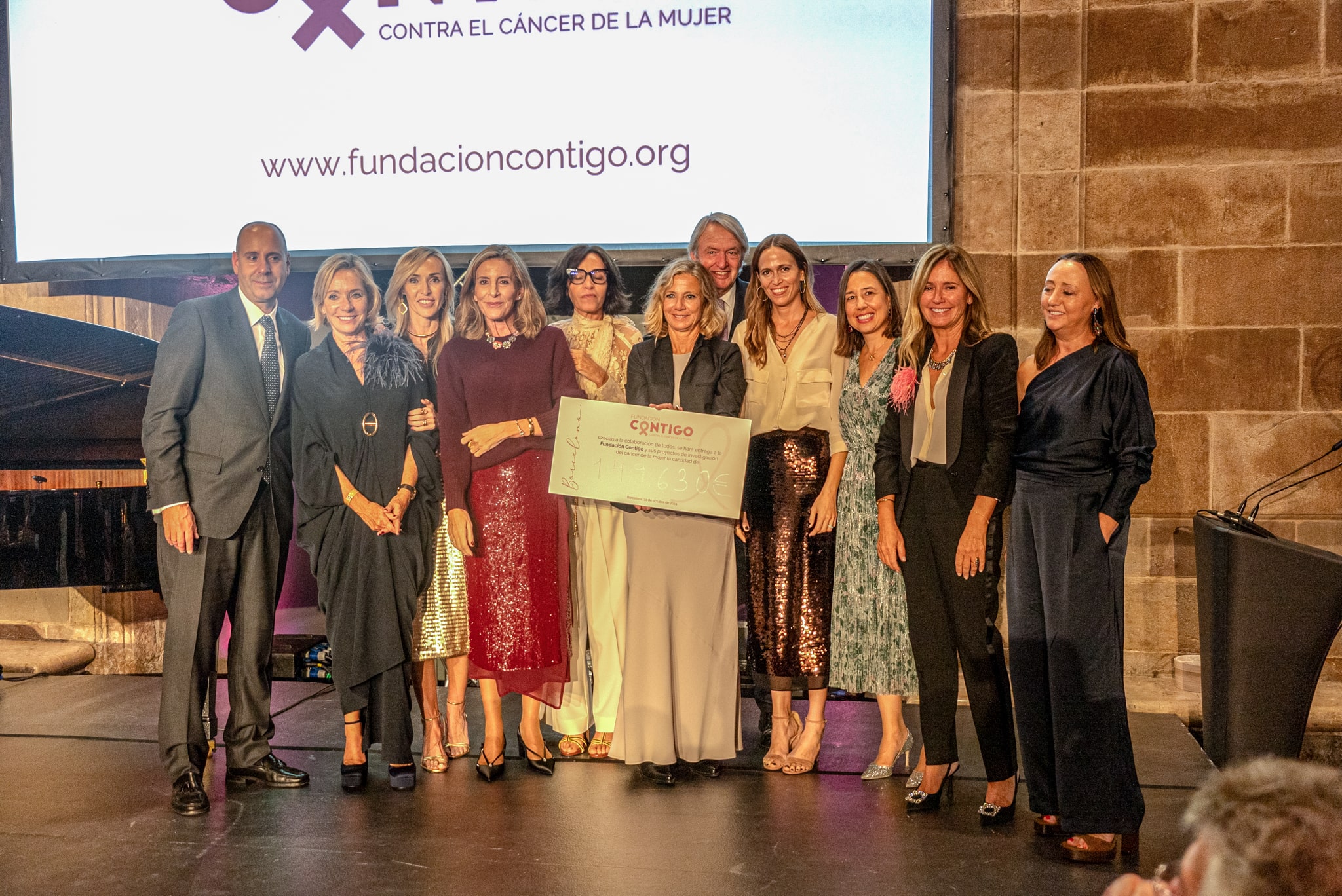

aggity Supports the Contigo Foundation at its Annual Dinner

Challenges and Opportunities of Generative AI in Industry: Our Experience at BNEW

Official Liferay Partner in Spain