Industrial Energy Saving Strategies

Optimizing energy consumption in factories, reducing costs and minimizing environmental impact are some of the advantages that can be achieved by implementing sustainable practices and advanced technologies.

Tabla de contenidos

ToggleDiscover how to reduce costs and improve sustainability with industrial energy saving strategies.

Nowadays, organizations in the industrial sector are constantly searching for ways to obtain the coveted “best in class” product. industrial energy savings: to opt for alternative energies, to implement self-supply systems or to incorporate specific solutions such as Smart Factory by aggity, which allow them to automate processes, are just some of the actions being carried out by companies in the sector to improve the energy efficiency in industry.

The fact is that the development of a strategy that achieves proper energy management in factories not only benefits the environment, but also has a very important impact on the competitiveness of companies in the industrial sector. Relying on energy-saving technologies or incorporating renewable energies in the industry are measures that are part of this strategy to obtain industrial energy savings, but there are also other important keys that must be taken into account.

Energy audit

Before developing an industrial energy saving strategy , it is necessary to know which are the improvement points that allow factories to obtain a better optimization of energy resources. In this case, the energy audit is the first step to achieve, for example, a reduction in electricity consumption or an improvement in machinery efficiency.

Thanks to this audit, companies will be able to identify areas for improvement in order to maximize energy efficiency . The aim is for companies in the industrial sector to carry out a detailed analysis of the systems, processes and equipment used in an industrial facility. In this way it will be possible to identify where energy leaks occur or which machines are inefficient.

The advantages of carrying out an energy audit are many, since it provides a complete overview of the company’s energy mix as a starting point for reducing operating costs, increasing competitiveness and meeting decarbonization and sustainability objectives.

Efficient technology

Most of the energy costs come from the consumption of the factory’s machinery. The commitment to renewable energies in industry is already a reality that improves the relationship between organizations and environmental protection, but it is not enough to reduce energy costs.

This requires energy-efficient machinery and equipment that comply with current regulations and standards. It is true that replacing older equipment with more modern ones requires an initial investment that can be considered high, but this is clearly compensated by the lower consumption, so that the return on investment is quick. For this reason, it is advisable to choose industrial energy-certified equipment that will enable this cost reduction and will serve to improve sustainability in production.

Automation and control

One of the important elements to improve industrial energy savings lies in the implementation of automation solutions. A solution such as PlanetTogether by aggity, combining data analytics and artificial intelligence, enables factories to automate production processes and thus improve process efficiency by reducing downtime.

In addition, these solutions minimize energy consumption by identifying where bottlenecks occur in the production chain and minimizing energy consumption, thereby reducing the product’s carbon footprint.

Últimos posts

aggity strengthens its commitment to sustainability as a SILVER partner of “Fundación Empresa & Clima”.

aggity participates in the IBM Ecosystem Summit 2024 with an applied case of Generative AI in the food industry

Aggity, together with the multinational Fortinet, present an exclusive event in Lima on the application of Generative AI in Corporate Cybersecurity.

aggity participates in Smart Ports: Piers of the Future

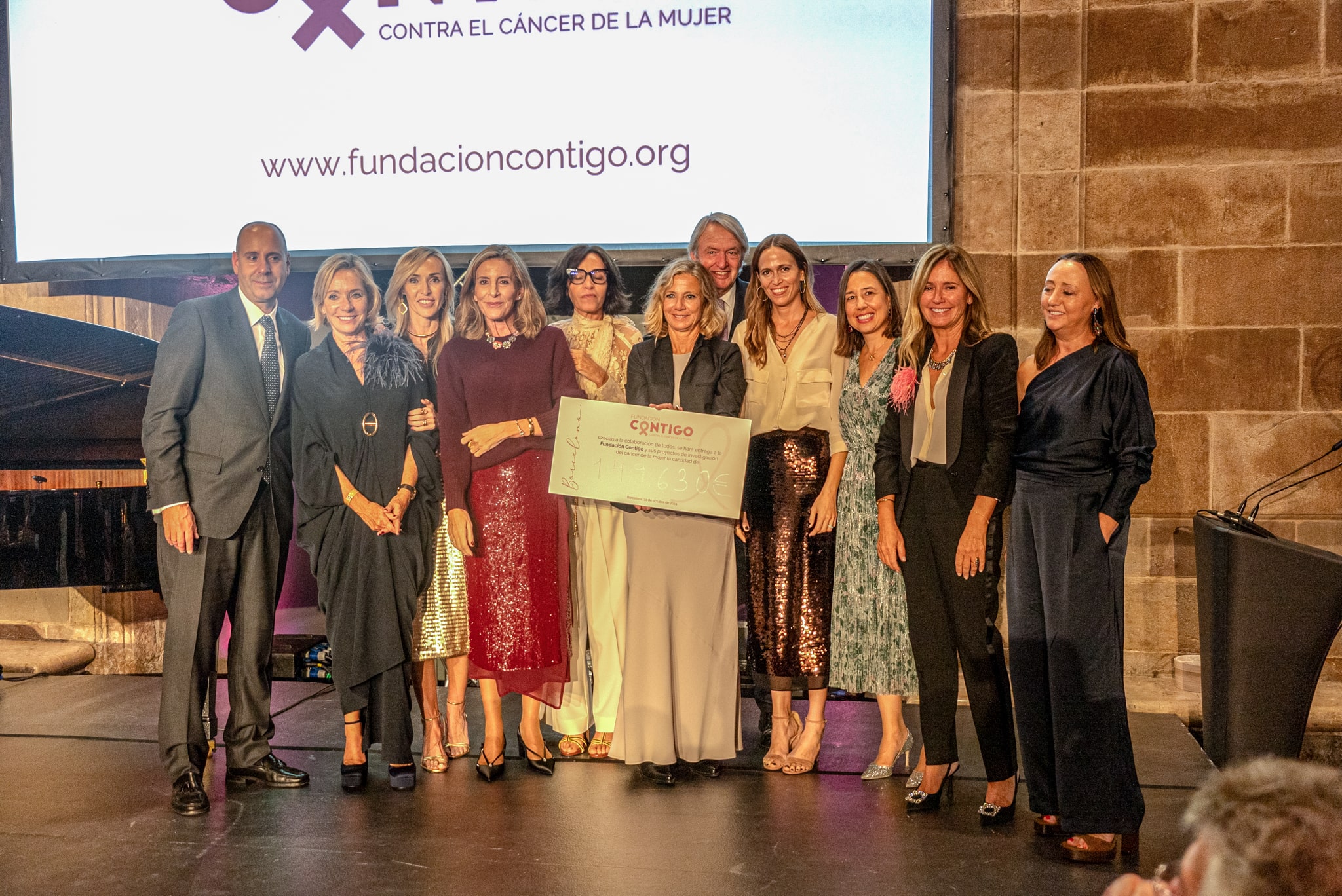

aggity Supports the Contigo Foundation at its Annual Dinner

Challenges and Opportunities of Generative AI in Industry: Our Experience at BNEW

Official Liferay Partner in Spain