Avoiding losses in industry with AI and Machine Learning

The use of artificial intelligence (AI) in industry will transform the companies that make up this sector in several areas, including inventory and stock management, where this technology promises to be a real revolution.

Tabla de contenidos

ToggleThe use of artificial intelligence in industry is of essential importance in supply chain management.

One of the traditional challenges facing any organization in the industrial sector is inventory management. The transition to Industry 4.0 with the use of automation tools aims to put an end to these problems, but there is one element that can make perfect stock management possible: artificial intelligence.

Far from the stardom of technologies such as ChatGPT, the truth is that the use of AI and Machine Learning in industry is contributing directly to the drive for Industry 4.0. The basis for the effective application of both technologies lies in the data.

The big advantage is that machine learning in the industry enables AI to develop and make decisions quickly based on the analysis of large amounts of data. With all this information, artificial intelligence allows to identify patterns that allow to predict the demand to be produced, so that it is possible to adjust stock levels and thus avoid product shortages or overstocking, which in turn reduces losses associated with unsold or expired products.

The use of artificial intelligence in Industry 4.0 and, in the future, in Industry 5.0, has already been in use for some time. Solutions such as Opera MES with aggity already cover a large part of the needs of today’s smart factory, offering a complete, modern, configurable and modular industrial management system that perfectly covers the management and control of Production, Quality, Materials and Maintenance activities.

Supply chain management

The use of artificial intelligence in industry is of essential importance in supply chain management. This is due to its ability to analyze data in real time, so that companies can identify and address problems that may arise. In this way, delivery delays are reduced, product quality is improved or production can be adjusted to take into account fluctuations in the price of raw materials. With this, the smart factory can make decisions to reduce the risk of losses.

With the use of AI in the industry, inventory management is optimized by implementing machine learning algorithms that are able to automatically adjust stock levels based on demand and market conditions. These algorithms can continuously analyze sales data, consumer behavior and other relevant factors to optimize inventory levels.

The value is in the data

Despite the prominence of AI and Machine Learning in the development of Industry 4.0, these two technologies are meaningless if there is no data on which they can work. Data is the food that both technologies need, so it is necessary to collect it from different sources.

The difficulty is that today there are many companies in the industrial sector that have not even begun to store data and many others do not have a strategy to collect and manage it efficiently, so they lose a large amount of vital information for business development.

More advantages of AI in industry

Once the data is well managed and analyzed, artificial intelligence and machine learning provide a number of other advantages such as the optimization of transportation and distribution routes as they are able to decide which are the best routes, improving efficiency and reducing costs. Likewise, loss and theft can also be prevented as Artificial Intelligence can detect suspicious patterns of activity in inventory and transportation.

Últimos posts

aggity strengthens its commitment to sustainability as a SILVER partner of “Fundación Empresa & Clima”.

aggity participates in the IBM Ecosystem Summit 2024 with an applied case of Generative AI in the food industry

Aggity, together with the multinational Fortinet, present an exclusive event in Lima on the application of Generative AI in Corporate Cybersecurity.

aggity participates in Smart Ports: Piers of the Future

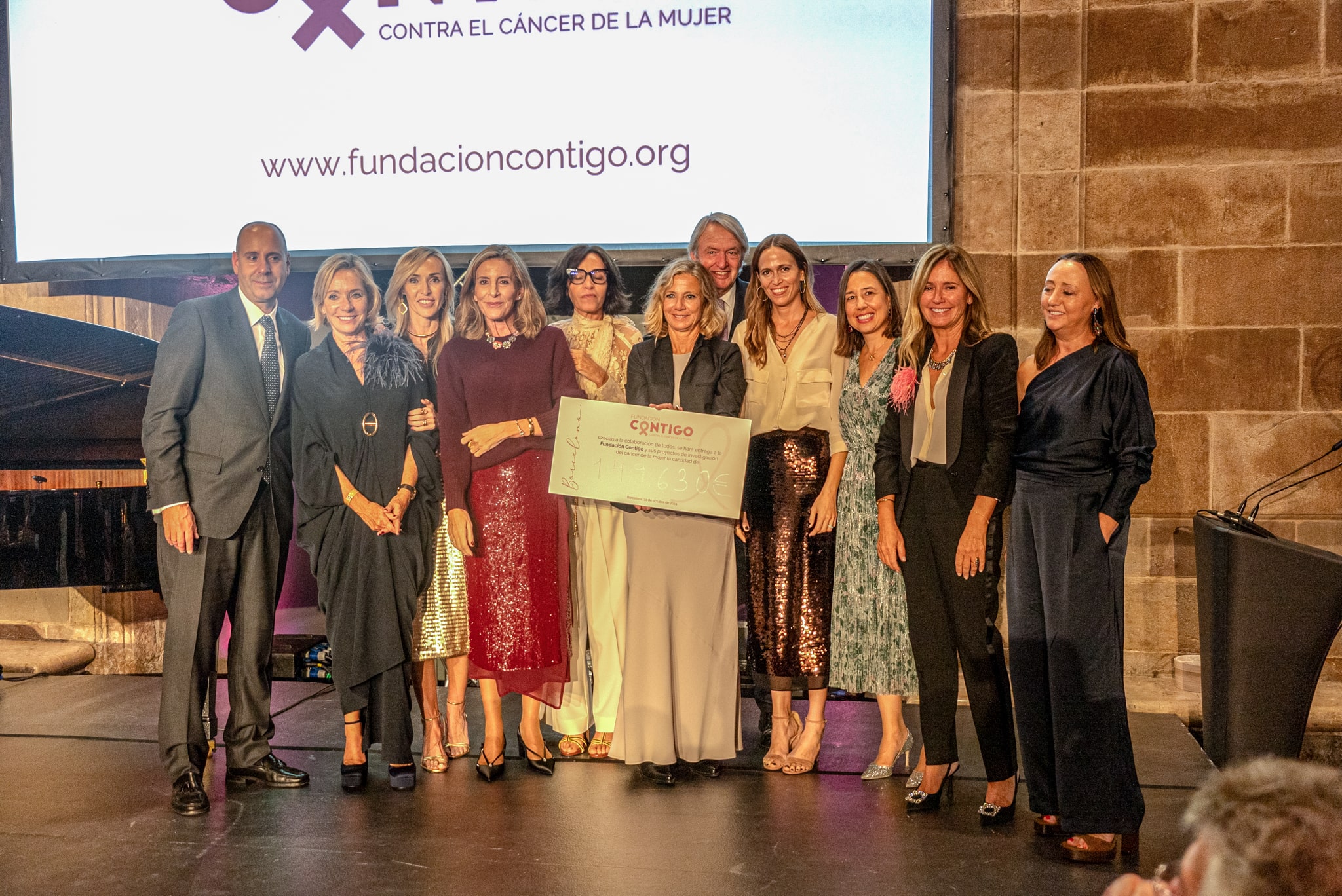

aggity Supports the Contigo Foundation at its Annual Dinner

Challenges and Opportunities of Generative AI in Industry: Our Experience at BNEW

Official Liferay Partner in Spain