Examples of Cobots in the Smart Factory: Innovative Automation

Collaborative robots, also called cobots, are one of the indispensable elements in Industry 4.0 and are already transforming factory production by improving both the efficiency and safety of manufacturing facilities.

Tabla de contenidos

ToggleDiscover how cobots are revolutionizing the Smart Factory with innovative automation.

Cobots are being used in industry on numerous occasions and are already bringing about a major revolution in manufacturing innovation. There are currently many examples of cobots that are providing innovative automation and producing production line optimization, pillars of smart manufacturing.

The transformation that industrial environments are undergoing would not be possible without the help of the collaborative robot. It is true that the automation in factories has long been incorporated into the production processes, but with the use of cobots, the next step is being taken, which is to achieve a innovative automation .

Thanks to her, the cobot integration and the use of smart factory technologies like Smart Factory by aggityplant and production managers see how a new plant is produced. human-robot collaboration This allows employees to dedicate themselves to tasks of greater value to the company and to do so with high levels of safety, since the riskier tasks are assimilated by the collaborative robot. Here are some examples of cobots in the smart factory.

Assembly of parts

The main feature of cobots, which are already a key part of smart factory work, is that they are designed to work safely alongside humans. These collaborative robots are equipped with advanced sensors that make it possible for them to adapt to an environment with a permanent presence of people and, since their programming is flexible, workers can teach them to perform different tasks without the need for programming skills.

Parts assembly is one of the environments where production efficiency has improved significantly with the use of cobots.

In this sense, the automotive sector is one of the sectors in which collaborative robots are being used the most. This is one of the most common cobot success stories, as in many automotive assembly plants these robots work alongside workers to perform repetitive and dangerous tasks, such as component assembly, welding and body painting.

Cobots are also widely used in the electronics industry, where they are used in the assembly of circuit boards as they ensure greater precision and speed in component placement.

Packaging and palletizing

In industrial robotization , cobots are increasingly being used for packaging and palletizing products. One of the sectors that is developing a greater number of cobot solutions is the food industry.

Organizations involved in food processing are employing this type of collaborative robot for product packaging, labeling and handling. The great advantage of its use is that, in addition to increasing productivity in the Smart Factory, it improves automation safety by preventing food contamination.

The use of cobots also extends to palletizing, thus resulting in a logistics optimization. Companies in this sector have seen how the use of collaborative robots makes it possible to optimize space in warehousesas well as reduce the physical strain on workers y streamline operations and receiving.

Handling of heavy materials

Other examples of cobot applications relate to the handling of heavy materials, which contributes to increased occupational safety. In this case it is a great help for those employees who have to move heavy loads that could cause injuries.

Organizations from different sectors are already using cobots in their innovative automation processes. The most relevant, the manufacturing industry and distribution, which employ cobots to lift and move heavy components on assembly lines, but they are also used in the construction sector to transport heavy materials on difficult terrain or in confined spaces.

Customer service and support

Another example can be found in cobots dedicated to customer service and assistance. In this case, we can see more and more collaborative robots in stores, airports, hotels, restaurants and other public places to provide information and assistance to customers.

Cobots can guide customers through the store, assist in finding items, move products and process payments. At airports we are already more than used to interacting with a collaborative robot to get a boarding pass or obtain information about the status of a flight.

Últimos posts

aggity strengthens its commitment to sustainability as a SILVER partner of “Fundación Empresa & Clima”.

aggity participates in the IBM Ecosystem Summit 2024 with an applied case of Generative AI in the food industry

Aggity, together with the multinational Fortinet, present an exclusive event in Lima on the application of Generative AI in Corporate Cybersecurity.

aggity participates in Smart Ports: Piers of the Future

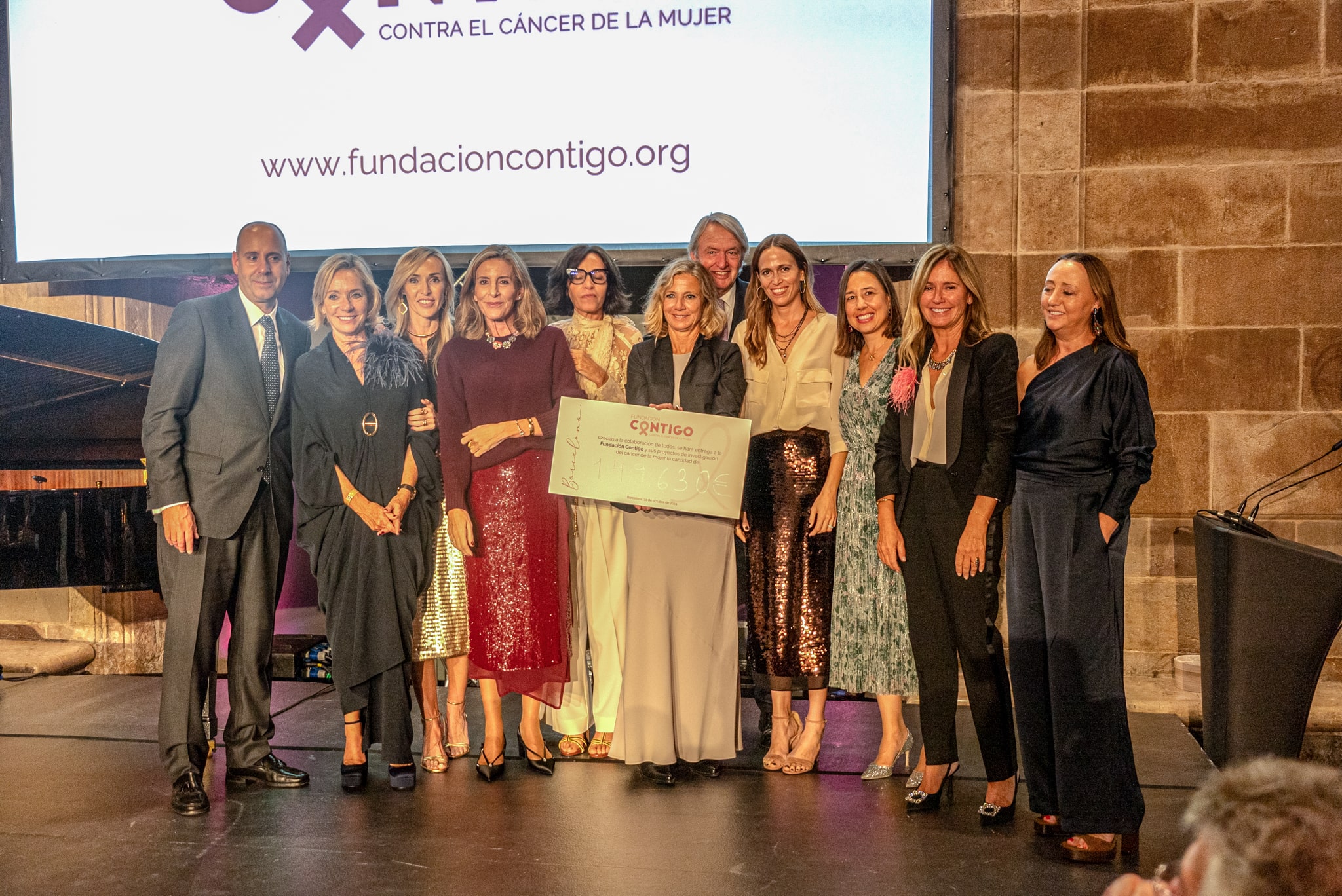

aggity Supports the Contigo Foundation at its Annual Dinner

Challenges and Opportunities of Generative AI in Industry: Our Experience at BNEW

Official Liferay Partner in Spain