The work of the future in the smart factory

The work of the future in the smart factory will necessarily involve collaboration between machines and human workers. Numerous projects are already in place to facilitate such cooperation.

Tabla de contenidos

ToggleMany of the projects to move towards the smart factory involve the incorporation of virtual reality.

It is not known for certain what all the jobs that will appear in the future will be. What is known is that, especially in smart factory and Industry 4.0 environments, the relationship between humans and machines is going to be greater. For this reason, different projects are being carried out with the aim of developing technologies that facilitate the creation of collaborative environments between machines and humans.

In general, in today’s industrial environments, machines and robots operate separately from employees, and that is what the smart factory is aiming to change. In the same way that, after the outbreak of the pandemic, collaborative work among employees was encouraged, with the incorporation of different tools, the work of the future in the smart factory is to create collaborative environments for workers and machines to work together in order to maximize the work done by both.

The work of the future will be collaborative

In short, the smart factory must be collaborative in all aspects and the technology must help on multiple fronts, not only in terms of intelligent product manufacturing. In this sense, technologies such as automation, virtual and augmented reality, adaptive interfaces, artificial intelligence and conversational chatbots are already being incorporated into smart factories and are making it possible for the work of the future to be more productive and collaborative.

Many of the projects to advance in smart factories 4.0 involve the incorporation of virtual reality. In this case, this technology helps in immersive training actions that make the worker believe that he/she is in a real environment. Something similar to pilots’ flight simulators, only in this case the virtual reality mimics the manual control of machining in a factory with the movements of the tool. The employee interacts thanks to mixed reality in such a way that he/she feels as if he/she is touching a real element.

Examples of smart factories

The innovations that are taking place are manifold. For example, natural language processing is enabling workers in a smart factory to directly engage in conversation with the robot to ask questions about a particular maintenance operation taking place in the factory and teach it how to resolve the situation.

And it is with mixed reality that a good part of the developments in the smart factory are taking place, especially in the assembly sections. In this case, a worker schedules the actions to be performed by a robot before it starts working on the task. Thanks to this mixed reality, it will be able to know if the robot’s performance will be correct and if so, the employee will give the order by voice for the robot to perform the job.

Tools such as those proposed in aggity ‘s catalog for Industry 4.0 are already making it possible to advance the work of the future in the smart factory. By employing new technologies such as data analytics or Artificial Intelligence, these types of solutions enhance collaboration between machines and workers, increase factory efficiency, planning capacity and product quality, and also provide the organization with better techniques to protect against cyber-attacks.

Advantages for machines and humans

The incorporation of all these types of solutions to move towards the smart factory will have a long way to go in the coming years. Its benefits will not only mean an increase in productivity for companies in the industrial sectorThe employees will be able to carry out their work more efficiently, which will translate into a improving workers’ well-being and quality of lifeThe worker will be forced to adapt to the technology, but the worker himself will be the one who will advance in his learning with the help of the machine.

Últimos posts

aggity strengthens its commitment to sustainability as a SILVER partner of “Fundación Empresa & Clima”.

aggity participates in the IBM Ecosystem Summit 2024 with an applied case of Generative AI in the food industry

Aggity, together with the multinational Fortinet, present an exclusive event in Lima on the application of Generative AI in Corporate Cybersecurity.

aggity participates in Smart Ports: Piers of the Future

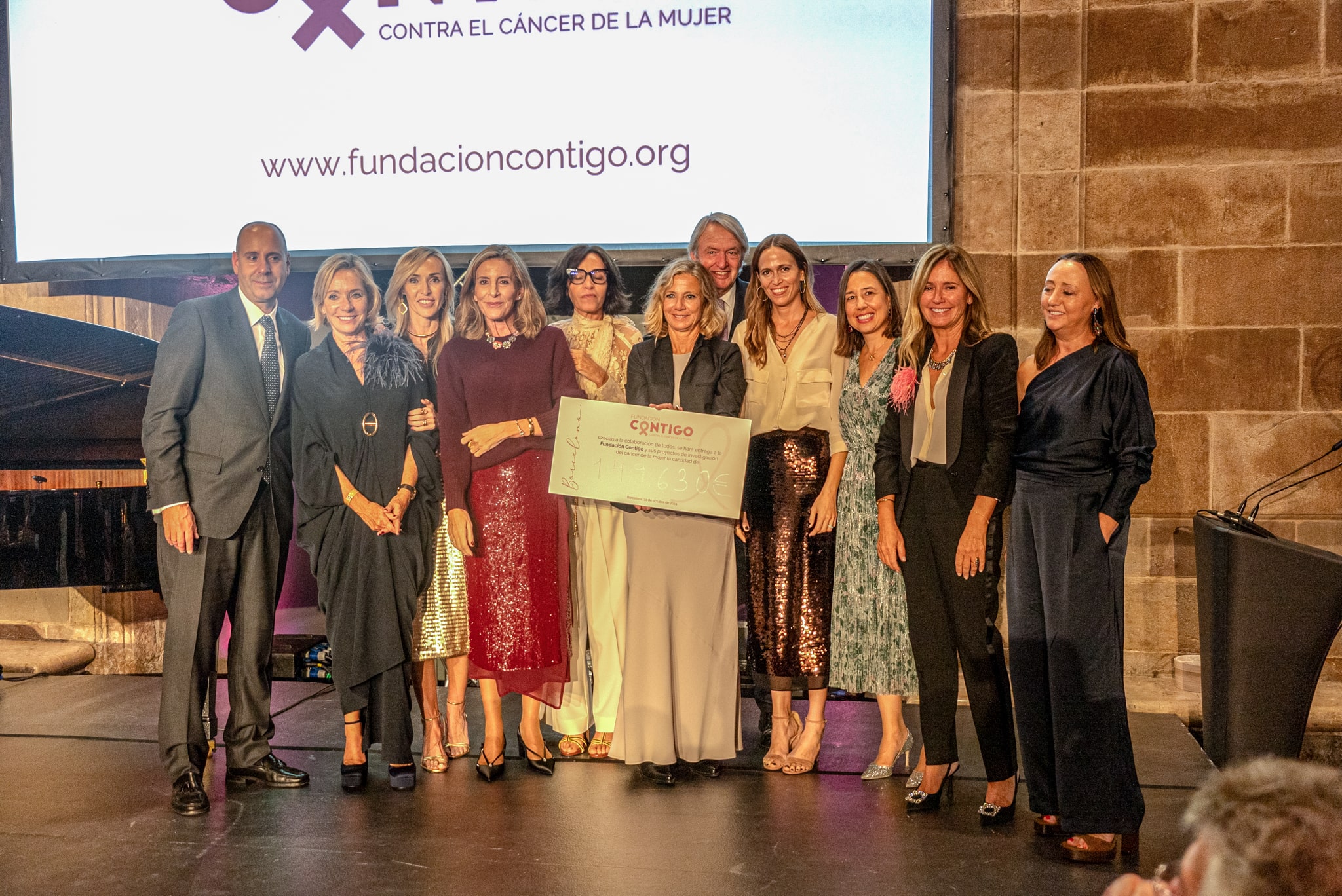

aggity Supports the Contigo Foundation at its Annual Dinner

Challenges and Opportunities of Generative AI in Industry: Our Experience at BNEW

Official Liferay Partner in Spain