Benefits of Industrial Automation

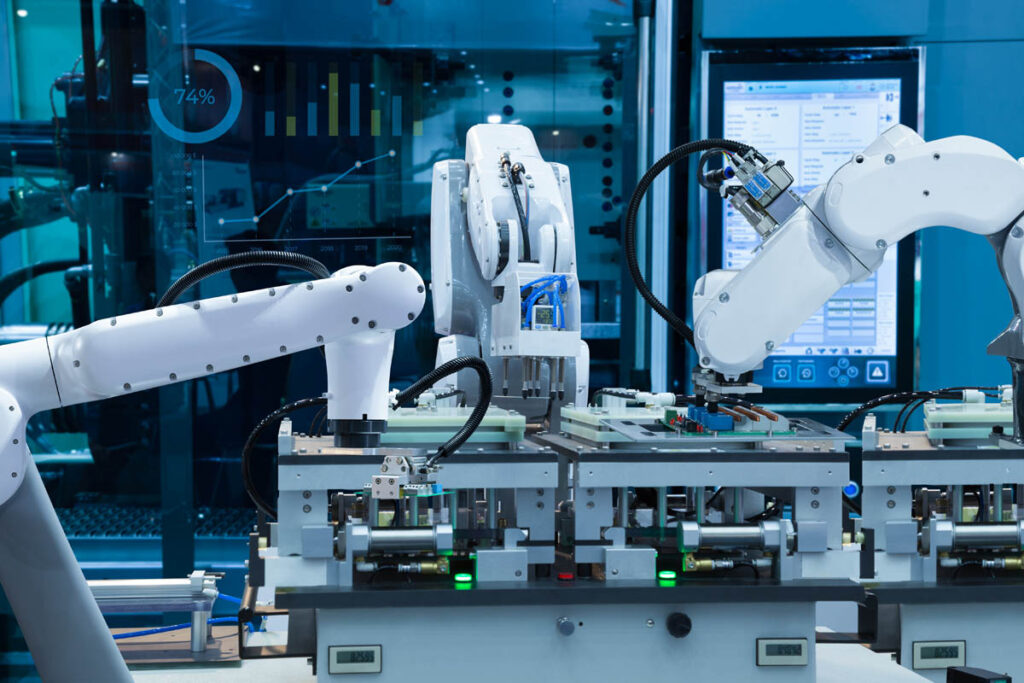

In the era of Industry 4.0, industrial automation has become a crucial component for the success of production plants. The smart factory, with its focus on integrating advanced technologies such as the Internet of Things (IoT) and big data, is leading this transformation.

Tabla de contenidos

ToggleDiscover the benefits of industrial automation in the optimization of a Smart Factory.

The benefits of industrial automation in smart factories range from process optimization and reduced operating costs to improved quality and sustainability. Next, we will discuss what the advantages of industrial automation are and how it provides valuable information to plant and production managers who can leverage these technologies to build a more efficient and competitive Smart Factory.

In industrial automation , specific technologies are used to perform production tasks and processes without the need for direct human intervention. Thanks to its use, production efficiency is improved, as well as the quality of the products.

In order to carry it out, automatic control systems, sensors and actuators, robotics, sensors, control and data analysis software, as well as tools and platforms such as Smart Factory by aggity, which covers all the needs of organizations in the industrial sector, are used. Among the benefits of industrial automation we can highlight the following:

Increased productivity

One of the main advantages of using industrial automation technologies is that it allows machines and systems to perform tasks faster and more efficiently than an employee would, resulting in increased productivity. In this sense, industrial automation makes it possible to minimize production cycle times by eliminating downtime and optimizing work sequences, resulting in faster and more efficient production.

Improved product quality

Robotization in manufacturing is already a reality so employing automation in an Industry 4.0 environment ensures consistent and controlled production, thereby improving the quality of the products being manufactured. This is possible because the defects that a human can commit are reduced, which also results in greater innovation in the plant . In addition, there is an improvement in the sustainability and manufacturing The automated supply chain makes better use of raw materials and reduces the amount of waste.

Reduction of operating costs

Another long-term benefit of industrial automation is that it helps to reduce costs by minimizing errors, reducing labor requirements and reducing production times. It is true that the initial investment in the implementation of automation technologies that improve process optimization will be high, but the return on investment will be much higher.

Improved occupational safety

This is one of the keys to industrial automation, since the work that was previously done by human employees is now being performed by machines or tools. In this way, the worker can not only dedicate himself to the performing tasks of greater value to the organizationThe company’s safety at work is improved because it can stop performing certain more dangerous jobs, such as handling chemicals or working in high temperature environments.

Production flexibility

The last major benefit is that automated systems can be reconfigured and programmed to suit different tasks and products. This ensures greater production flexibility as the use of automation tools allows smart factories to quickly adapt to changes in demand and modify production configurations. All of this results in greater agility in responding to changing needs and continuous improvement in operational efficiency.

Últimos posts

IBM Think 2024 bets on Generative Intelligence and It Automation solutions

aggity participates in the “Mobility Dialogues” meeting organized by IN-MOVE by Railgrup

aggity appoints Diego Viudes as new commercial director for the spanish business

Key developments in green innovation

Aggity signs a commercial agreement with Sener to address energy efficiency and decarbonization projects in the industrial sector.

“Sustainability, without data, is simply a pipe dream.”

Improvements in corporate data protection